21

Cool only control:ON-OFF control, P (PD) control and PID control can be used for cooling control. Set OUT1

to DIRT (direct action). The other functions for cool only ON-OFF control, cool only P (PD) control and cool

only PID control are the same as the descriptions for heat only control, except that the output variable (and

action) for the cool control is inverse to the heat control.

Cool only control:

NOTE: ON-OFF control may result in excessive overshoot and undershoot problems in the process. The P (or PD)

control will result in a deviation of process value from the set point. It is recommended to use PID control for the

Heat-Cool control to produce a stable and zero offset process value.

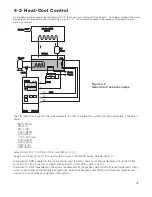

CYC1, CYC2, O1FT, O2FT O1TY & O2TY parameters are set in accordance with the types of

OUT1 & OUT2 installed. CYC1 & CYC2 are selected according to the output 1 type (O1TY) & output 2 type (O2TY)

Generally,

select 0.5 ~ 2 sec. for CYC1;

10 ~ 20 sec;

and

CYC1 is ignored. Similar settings are applied for CYC2 selection.

Other Setup Required:

Cycle Time:

if SSRD or SSR is used for O1TY,

if relay is used for O1TY, select

if linear output is used,

NOTE:

Other Setup Required:

Cycle Time:

You can use the

program for a new process or directly set the appropriate values for PB, TI & TD

according to the historical records for the repeated systems. If the control behavior is still inadequate, then use

to improve the control. See

for manual tuning.

auto-tuning

manual tuning

section 3-12

auto-tuning

manual tuning

section 3-12

CPB Programming: The cooling proportional band is measured by % of PB with range 50~300. Initially set 100% for

CPB and examine the cooling effect. If cooling action should be enhanced then decrease CPB, if cooling action is too

strong then increase CPB. The value of CPB is related to PB and its value remains unchanged throughout the auto-

tuning procedures. Adjustment of CPB is related to the cooling media used. For air used as a cooling media, adjust

CPB to 100(%). For oil is used as a cooling media, adjust CPB to 125(%). For water used as cooling media, adjust

CPB to 250(%).

CPB Programming:

DB Programming: Adjustment of DB is dependent on the system requirements. If more positive value of DB (greater

dead band between heating and cooling) is used, an unwanted cooling action can be avoided but an excessive

overshoot over the set point will occur. If more negative value of DB (greater overlap) is used, an excessive overshoot

over the set point can be minimized but an unwanted cooling action will occur. It is adjustable in the range -36.0% to

36.0 % of PB. A negative DB value shows an overlap area over which both outputs are active. A positive DB value

shows a dead band area over which neither output is active.

DB Programming:

Output 2 ON-OFF Control (Alarm function):

DE.HI

DE.LO

DB.HI

DB.LO

PV.HI

PV.LO

Figure 3.3

Figure 3.4

The output 2 can also be configured as alarm function. There are 6 kinds

of alarm functions can be selected for output 2, these are:

(deviation high alarm ),

(deviation low alarm),

(deviation band out of band alarm),

(deviation band in band alarm),

(process high alarm) and

( process low alarm ). Refer to

and

for the description of deviation alarm and process

alarm with normal alarm mode.

Output 2 ON-OFF Control (Alarm function):

DE.HI

DE.LO

DB.HI

DB.LO

PV.HI

PV.LO

Figure 3.3

Figure 3.4