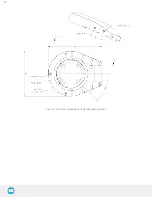

Tip

To perform a click button action, as shown by the animated GIF, a Find Surface function has to be added up in the Click

detection node.

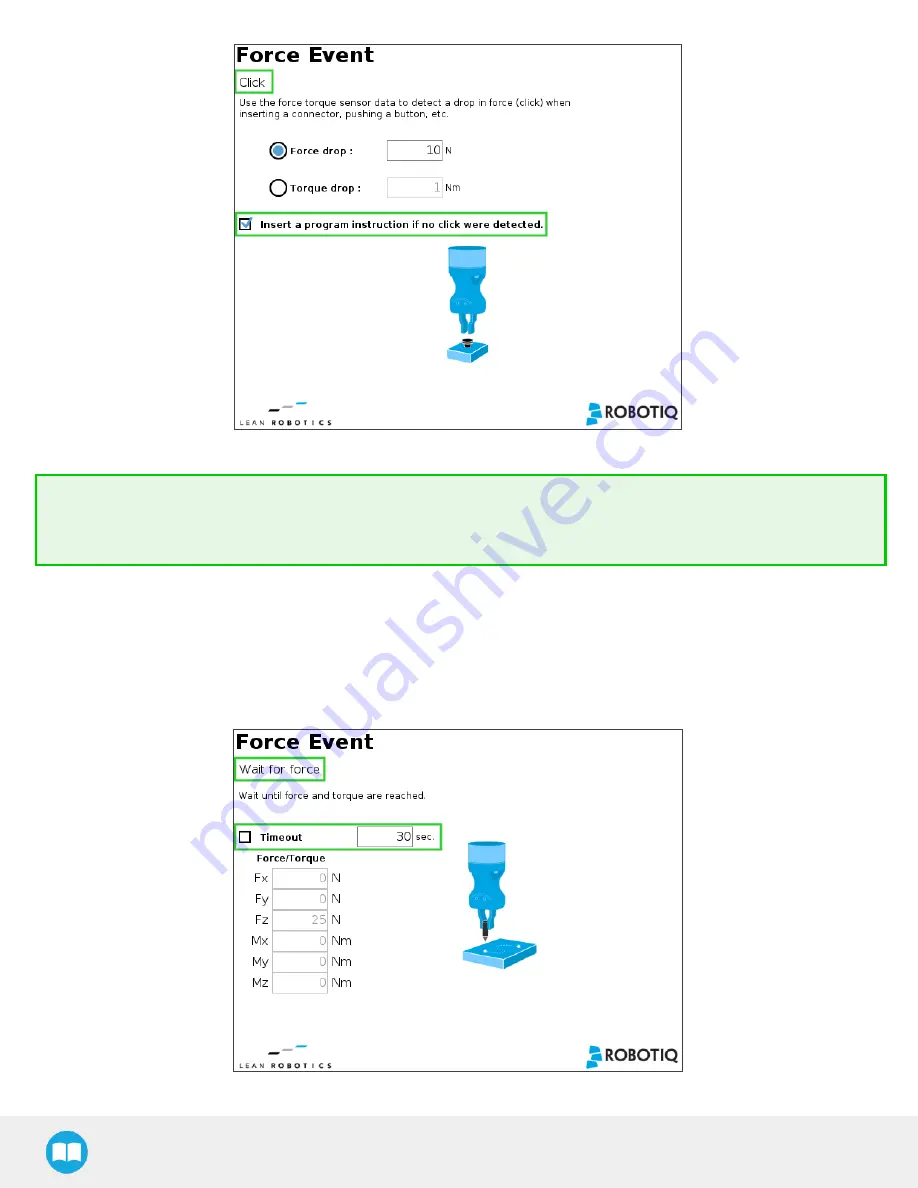

4.14.2. Features (Wait for Force)

The Wait for Force feature is used to detect a specific force or torque inside a Force Control node. The program waits until the

force or torque is reached prior to the program continuation. The values are defined by the Force Control's force and torque

parameters. To be sure the program is not incessantly running, a Timeout option is available.

77