Vishay Micro-Measurements

System 7000 Programmer’s Reference Manual

Page 52 of 142

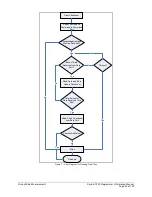

4 SYSTEM STATUS AND ERROR HANDLING

The System 7000 provides two methods for monitoring the status and error information. You may query

the system via TCP commands or you may monitor the UDP Event port.

The advantage of querying for status information is that it is typically easier to implement

programmatically. The disadvantage is that if you too frequently query the status information you will

significantly degrade the performance of the System 7000.

The alternative is monitoring the UDP Event Port for status information. This typically involves setting

up a background task (or similar) to monitor the port. The advantage is that you are not burdening the

system with a large amount of TCP traffic and its performance will remain at an optimal level.

4.1 Error Handling

There are several different methods of programmatically handling errors and tracking the status of your

System 7000.

Command / Query Responses

When a command or query is passed to the System 7000 a response is returned indicating if the

command is successful (ACK) or if it failed (NAK). If the command failed, an error number is

returned indicating the cause of the failure. You should always perform the appropriate error

handling on command responses.

LabVIEW

Each VI uses the standard “error output” indicator. Any

errors detected in a command response will be reported in

this indicator.

Active X

Most methods return a result status. If the result is 0, then

the method was successful. If an error is detected in a

command response, the error number is passed as the

result. The last result status is also found in the

LastErrorCode property. Every method updates this

property. LastErrorCode=0 indicates No Error. Other

values represent error codes.

Low-level

You must monitor the TCP port for the command response.

Each response will indicate an ACK or a NAK.

Event Messages

Event (error or status change) messages are also broadcast over the UDP Event/Status Port.

There is more information on monitoring these messages later in this section.

Error Log

The System 7000 also maintains an error log file (“Error.Log”) on each card and on the control

module. It is possible to download this file and examine the contents. It is maintained as a

standard, ASCII text file. A snippet from an error log file is shown below. Each line is

terminated by a linefeed character (0x0A).

08/01/2008 00:00:25 Error Code = 165, Cannot initialize date and time

08/20/2008 18:40:28 Error Code = 55, Cannot open or read file for transfer

LabVIEW

Retrieve File VI

Active X

RetrieveFile() method

Low-level

You may start the retrieval of the error log file with the

Retrieve File command. You must also monitor the data

port for the file contents.