2-5

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

2.3

Configuring the Preferences for STEP 7-Micro/WIN

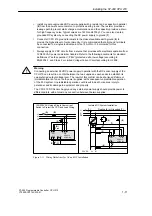

Before creating a new project, specify the preferences for your programming environment. To

select your preferences, follow these steps:

1. Select the menu command Setup

"

Preferences... as shown in Figure 2-3.

2. Select your programming preferences in the dialog box that appears.

3. Confirm your choices by clicking the “OK” button.

✂

Preferences

Cancel

OK

English

STL Editor

Ladder Editor

Default Editor

International

SIMATIC

Mnemonic Set

Program Editor

Initial Window States

Language

Data Block Editor

Maximize All

Symbol Table

Status Chart

Project Edit View CPU Debug Tools Setup Window Help

Setup

Preferences...

Communications...

Normalized

Minimized

Minimized

Minimized

Options for an Uploaded Data Block

Data Format

Retain Format and Comments

Data Size

Hexadecimal

Byte

Figure 2-3

Selecting Your Programming Preferences

Installing and Using the STEP 7-Micro/WIN Version 2.0 Software

Summary of Contents for Simatic S7-200 CPU 210

Page 10: ...x S7 200 Programmable Controller CPU 210 C79000 G7076 C235 01 Contents ...

Page 116: ...A 16 S7 200 Programmable Controller CPU 210 C79000 G7076 C235 01 CPU 210 Data Sheets ...

Page 126: ...F 2 S7 200 Programmable Controller CPU 210 C79000 G7076 C235 01 CPU 210 Order Numbers ...

Page 138: ...Index 12 S7 200 Programmable Controller CPU 210 C79000 G7076 C235 01 Index ...