19

UBI EasyCoder 501 – Technical Manual

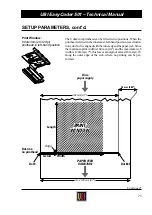

SETUP PARAMETERS, cont'd.

Continued!

Serial Communication

• Baudrate

• Parity

• Character Length

• Stop Bits

• Flow Control

• New Line

Contrast

This chapter explains the meaning of the various setup parameters.

There are different ways to change the setup:

• By means of the Setup Mode, see the chapters “Setting Up

EasyCoder 501” and ”Setting Up EasyCoder 501 E & 501 SA”.

• By means of the Terminal Setup option in UBI Shell, see the UBI

Shell Standard and Enhanced Startup Manuals.

• By means of setup files or setup strings. See the UBI Fingerprint

Reference Manual,

SETUP

statement, or the UBI Direct Protocol

Programmer's Guide.

Note that the following setup options are excluded in the Easy-

Coder 501 printer model:

• Serial communication setup for communication channels "uart2:"

and "uart3:" (no extra serial interface boards can be connected).

• Communication buffer setup for communication channels "uart2:"

and "uart3:" (no extra serial interface boards can be connected).

• Performance setup (fixed print speed setup).

The contrast setup allows you to make minor adjustment of the

printout in regard of blackness, e.g. to adapt the printer to variations

in quality between different batches of the same paper quality.

The serial communication setup controls the communication be-

tween the printer and the connected computer or other devices on

the standard serial channel "uart1:" and the optional serial channels

"uart2:" and "uart3:". The latter two channels require an optional

interface board to be fitted. The printer's firmware detects if an

optional interface board is fitted and presents additional sets of

communication setup menus for each serial channel.

The serial communication setup has no consequence whatsoever

for parallel communication via an optional parallel interface

board or for the

IN

and

OUT

ports on the optional Industrial

Interface Board.

For each serial communication channel, the following parameters

can be set. Make sure they match the setup of the connected device

or vice versa. The default setup (indicated by bold characters below)

is selected as to make the printer understand and act upon UBI

Fingerprint instructions transmitted from the host, regardless how

the host is set up. If the setup of the printer and the setup of the host

do not match, the response from the printer to host will be garbled.