6. Description of Parameters

- 192 -

6

6.10 Communication

The drive support communication links, such as Modbus, PROFIBUS-DP, CANlink (always valid), or

CANopen.

You can monitor and control of the AC drive, for example, view or modify function parameters by using

a host computer.

Make sure to set communication parameters correctly. Otherwise, communication may fail.

Function Code

Parameter Name

Setting Range

Default

F0-28

Serial port communication

protocol

0: Modbus protocol

1: PROFIBUS-DP or CANopen protocol

0

Fd-00

Baud rate

0000 to 6039

5005

Fd-01

Modbus data format symbol

0 to 3

0

Fd-02

Local address

0: Broadcast address

1 to 247

1

Fd-03

Modbus response delay

0 to 20

2

Fd-04

Serial port communication

timeout

0.0 (Invalid)

0.1 to 60.0

0.0

Fd-05

Modbus protocol selection

and PROFIBUS-DP data

frame

00 to 31

30

Fd-06

Current resolution read by

communication

0 to 1

0

Fd-08

CANlink communication

timeout time

0.0 (Invalid)

0.1 to 60.0

0

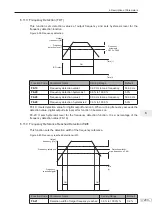

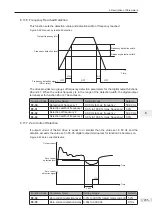

6.10.1 Read and Write Function Parameters

Ƶ

Read Function Parameters

For function parameters in groups F0 to FF and A0 to AF, the highest eight bits in

communication address indicate function code group, while the lowest eight bits indicate

hexadecimal number converted from SN in function code group.

For example, communication address of F0-16 is F010H, in which F0H indicates

function code group F0 and 10H is the hexadecimal number converted from 16.

Communication address of AC-08 is AC08H, in which ACH indicates function code group

AC and 08H is the hexadecimal number converted from 8.

To read desired function parameter, host computer needs to send a read command to

the AC drive. Here takes the Modbus protocol as an example to describe communication

process of reading the drive data.

For example, to read F0-10, read command is 01 03 F0 0A 01 DE D7 (hexadecimal). In

the command,

Ɣ

01H (settable): AC drive address

Ɣ

03H: read command

Ɣ

F00AH: communication address of F0-10

Ɣ

01H: number of function parameters

Ɣ

DED7H: CRC check

Summary of Contents for MD290 Series

Page 1: ......

Page 79: ...3 Electrical Installation 78 3 ...

Page 80: ...4 Operating Panel Keypad Display 4 1 Introduction 80 4 2 Inbuilt LED Operating Panel 80 ...

Page 92: ...5 Quick Setup 5 1 Get Familiar With Operating Panel 92 5 2 Setup Flowchart 93 ...

Page 227: ...7 Interfaces and Communication 226 7 ...

Page 285: ...10 Troubleshooting 284 11 ...

Page 349: ......

Page 350: ......