TRIO MPC-145 SERIES MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 2.62C (20191001) (FW V2.62)

50

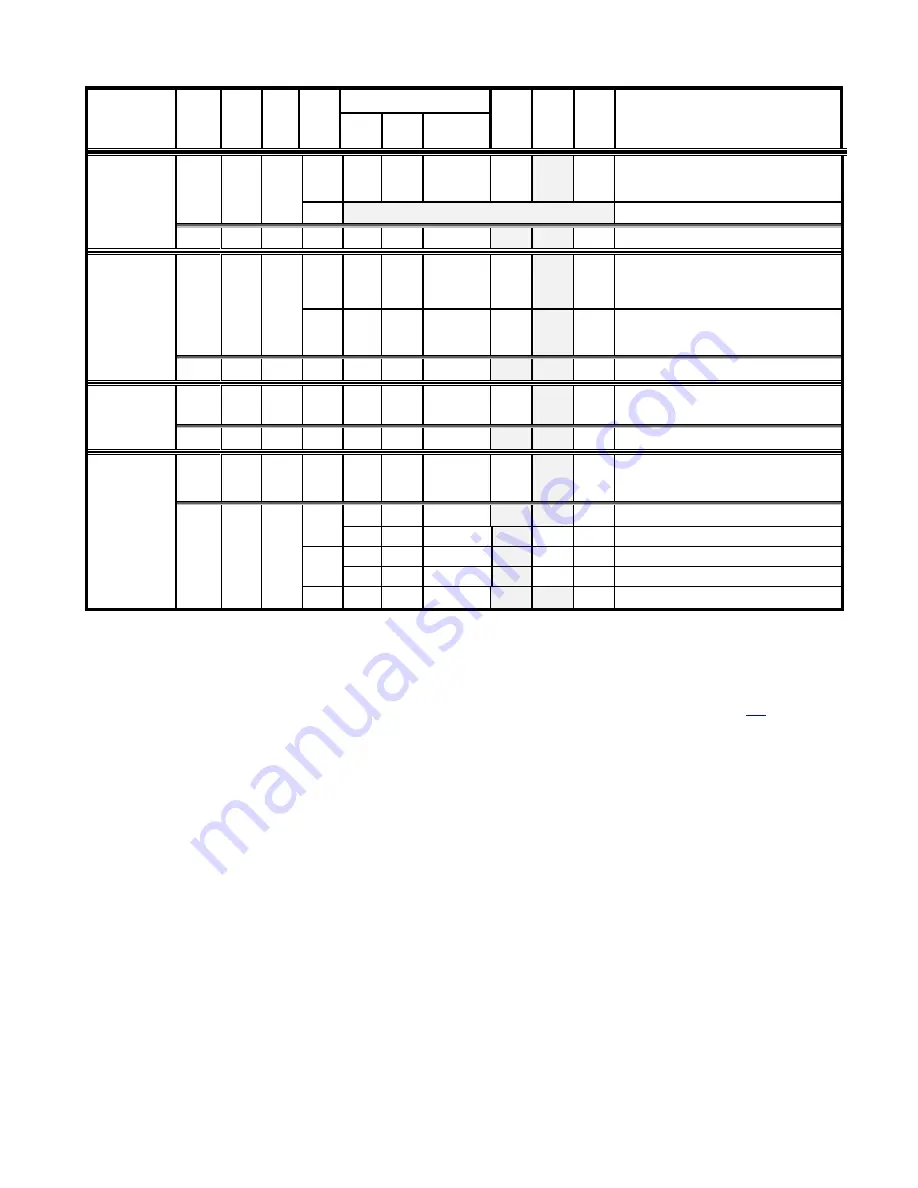

Command

Tx/-

Delay/-

Rx

Ver. Total

Bytes

Byte

Offset

(Len.)

Value

Alt-

key-

pad #

Ctrl-

char

ASCII

def./-

char.

Description

Dec. Hex. Binary

Move to

specified Z

axis Position

(‘z’ or ‘Z’)

Tx

All

5

0

122

or

92

7A

or

5C

0111 1010

or

0101 1100

0122

or

0092

‘z’

or

‘Z’

Command. Move Z-axis to specified

position (see

Ranges

table).

1 (4)

Z µsteps

Rx

All

1

0

13

0D 0000 1101

<CR>

Completion indicator

Enter Angle

(‘A’)

Tx

All

2

0

65

41 0100 0001 0065

‘A’

Command. Sets the angle value, in

degrees, to match the angle position

of the rotary dovetail.

1

0

-

90

00

-

5A

0000 0000

-

0101 1010

0000

-

0090

<NUL>

-

‘z’

Angle in degrees between 0 and 90.

See

Angle Setting & Movement

note

Rx

All

1

0

13

0D 0000 1101

<CR>

Completion indicator

Recalibrate

(‘R’)

Tx

2.6

1

0

82

52 0101 0010 0082

‘R’

Command. Causes the currently

active manipulator to recalibrate.

Rx

2.6

1

0

13

0D 0000 1101

<CR>

Completion indicator

Query

Moving State

(‘q’ or ‘Q’)

Tx

2.6

1

0

81

or

113

51

or

71

1001 0001

or

0111 0001

0081

or

0113

‘q’

or

‘Q’

Command. Reports the state of

movement for each device.

Rx

2.6

3

0

0

00 0000 0000

^@ <NUL>

Device 1: Not moving

1

01 0000 0001

^A <SOH>

Device 1: Movement in progress

1

0

00 0000 0000

^@ <NUL>

Device 2: Not moving

1

01 0000 0001

^A <SOH>

Device 2: Movement in progress

2

13

0D 0000 1101

<CR>

Completion indicator

NOTES:

1.

Task-Complete Indicator: All commands will send back to the

computer the “Task-Complete Indicator” to signal the

command and its associated function in controller is

complete. The indicator consists of one (1) byte containing a

value of 13 decimal (0D hexadecimal), and which represents

an ASCII CR (Carriage Return).

2.

Intercommand Delay: A short delay (usually around 2 ms) is

recommended between commands (after sending a command

sequence and before sending the next command).

3.

Clearing Send/Receive Buffers: Clearing (purging) the

transmit and receive buffers of the I/O port immediately

before sending any command is recommended.

4.

Positions in Microsteps: All positions sent to and received

from the controller are in microsteps (µsteps). See

Microns/-

microsteps conversion table) for conversion between µsteps

and microns (micrometers (µm)).

5.

Ranges and Bounds: See

Ranges and Bounds table for exact

minimum and maximum values for each axis of each

compatible device that can be connected. All move commands

must include positive values only for positions – negative

positions must never be specified. All positions are absolute

as measured from the physical beginning of travel of a

device’s axis. In application programming, it is important

that positional values be checked (>= 0 and <= max.) to

ensure that a negative absolute position is never sent to the

controller and that end of travel is not exceeded. All

computational relative positioning must always resolve to

accurate absolute positions.

6.

Absolute Positioning System Origin: The Origin is set to a

physical position of travel to define absolute position 0. The

physical Origin position is fixed at beginning of travel (BOT).

This means that all higher positions (towards end of travel

(EOT)) are positive values; there are no lower positions and

therefore no negative values are allowed.

7.

Absolute vs. Relative Positioning: Current position (‘c’) and

move commands always use absolute positions. All positions

can be considered “relative” to the Origin (Position 0), but all

are in fact absolute positions. Any position that’s considered

to be “relative” to the current position, whatever that might

be, can be handled synthetically by external programming.

However, care should be taken to ensure that all relative

positions are accurately translated to correct absolute

positions before initiating a move command.

8.

Position Value Typing: All positions sent and received to and

from the controller are in microsteps and consist of 32-bit

integer values (four contiguous bytes). Position values can be

either positive or negative, so type must be “signed”.

Although each positional value is transmitted to, or received

from, the controller as a sequence of four (4) contiguous

bytes, for computer application computational and storage

purposes each should be typed as a signed integer (“long” or

“signed long” in C/C++; “I32” in LabVIEW, etc.). Note that

in Python, incorporating the optional NumPy package brings

robust data typing like that used in C/C++ to your program,

simplifying coding and adding positioning accuracy to the

application.