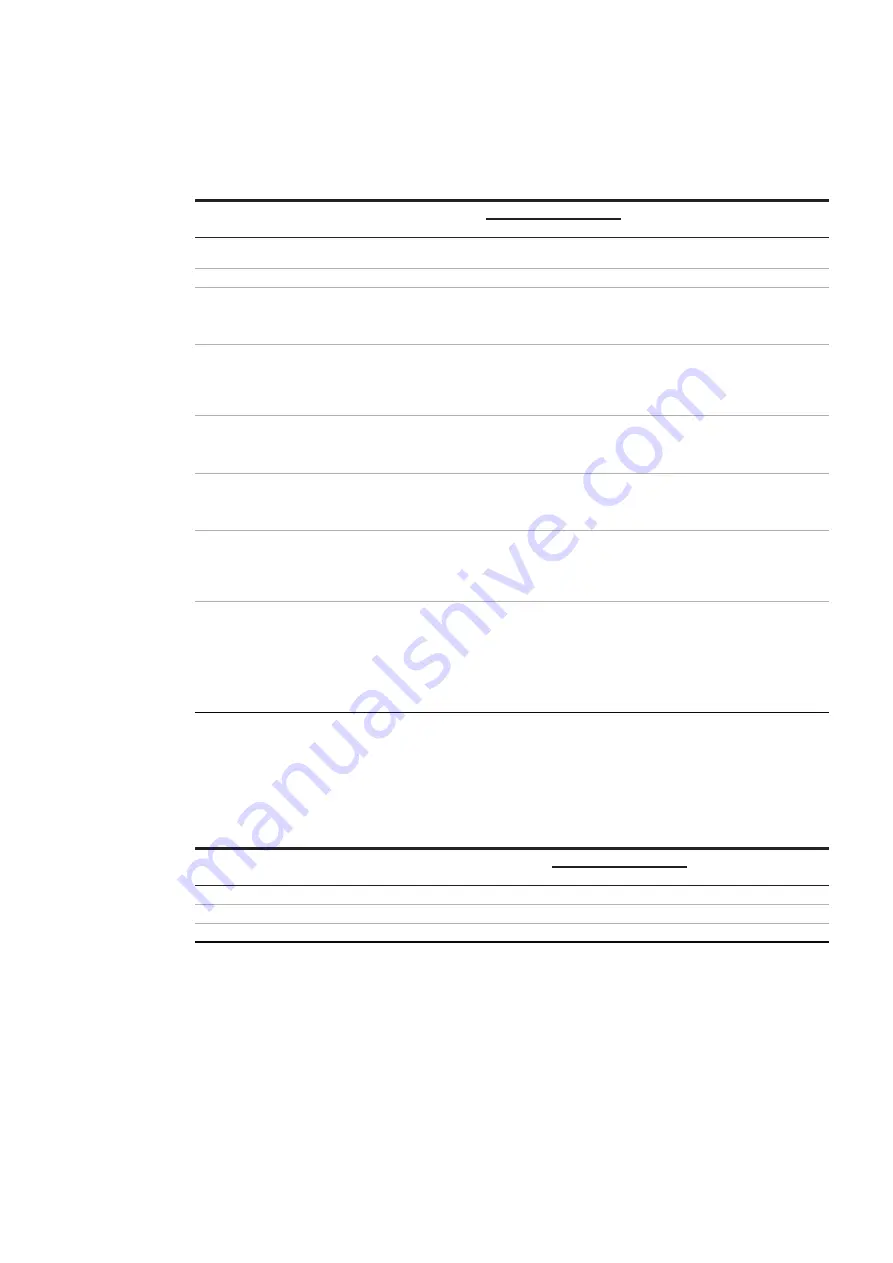

USER I N T ER FAC E

17

Name

Address

Unit

Type

Register

length

Range

Description

Min.

Max.

ESI Active Power

30811

kW

Float

2

-3200

3200

Inverter active power

ESI Reactive Power

30813

kvar

Float

2

-3200

3200

Inverter active power

ESI Apparent Power

30815

kVA

Float

2

-3200

3200

Inverter active power

Name

Address Unit

Type

Register

length

Range

Description

Min.

Max.

Node Status[0]

31102

-

Word

16

0

2

NodeStatus 1 to 16:

Reports the status of the unit

AIP State

31118

-

Byte

1

0

2

Status of the unit

Output Status

31123

-

Byte

1

0

0xFF

Reporting the status

of 4 outputs

(For instance if DC contact

and DC preload closed, report 10)

Current

UC Error

32801

-

Dword

2

0

0xFFFFFFFF

The current error was detected

by the UC. Please refer to the

description of "CurrentUCError" for

the list of possible UC errors,

corresponding bit is set in register

Current

DSP Error

32803

-

Dword

2

0

0xFFFFFFFF

The current error was detected

by the DSP. Please refer to the

description of"CurrentDSPError" for

the list of possible DSP errors

Islanding

Status

36201

-

Dword

2

0

2

When set (1) means that unit is in

Islanding mode, when cleared (0), it is

in grid-connected mode

(Available in the future)

Black Started

36207

-

Dword

2

0

1

When set (1), the unit is in

black start condition; once it

has reached the "running"

state, it is cleared (0),

(Available in the future)

Fault Stop

Error

32866

-

Dword

2

0

0xFFFFFFFF

Stores the latest error code that has

prevented the unit from restarting. If

MSBit is set (0x80000000), error was

detected by DSP and decoding must

be taken from "CurrentDSPError", if

MSBit not set, then error was detected

by UC and decoding must be taken

from "CurrentUCError"

3.9.2 System monitoring

Table 9 lists Modbus commands to monitor the state of the PQstorI system. These functions are

described further in Sections 3.7.1 and 3.7.3.

—

Table 9: Modbus commands to monitor the PQstorI

3.9.3 Power monitoring

Table 10 lists Modbus commands to monitor the power on the network and injected by the PQstorI.

These function are described further in Sections 3.4.5 and 3.7.3.

—

Table 10: Modbus commands to monitor the power injected by the PQstorI onto the grid