Chapter 5 Function parameter

78

Ch

ap

ter 5

Define the output terminal SPA, SPB, relay 1, relay 2 output logic.

0: positive, digital output terminal and the corresponding public terminal connectivity to the

active state, disconnecting is inactive state;

1: negative, digital output terminal and the corresponding public terminal connectivity to the

inactive state, disconnecting is active state.

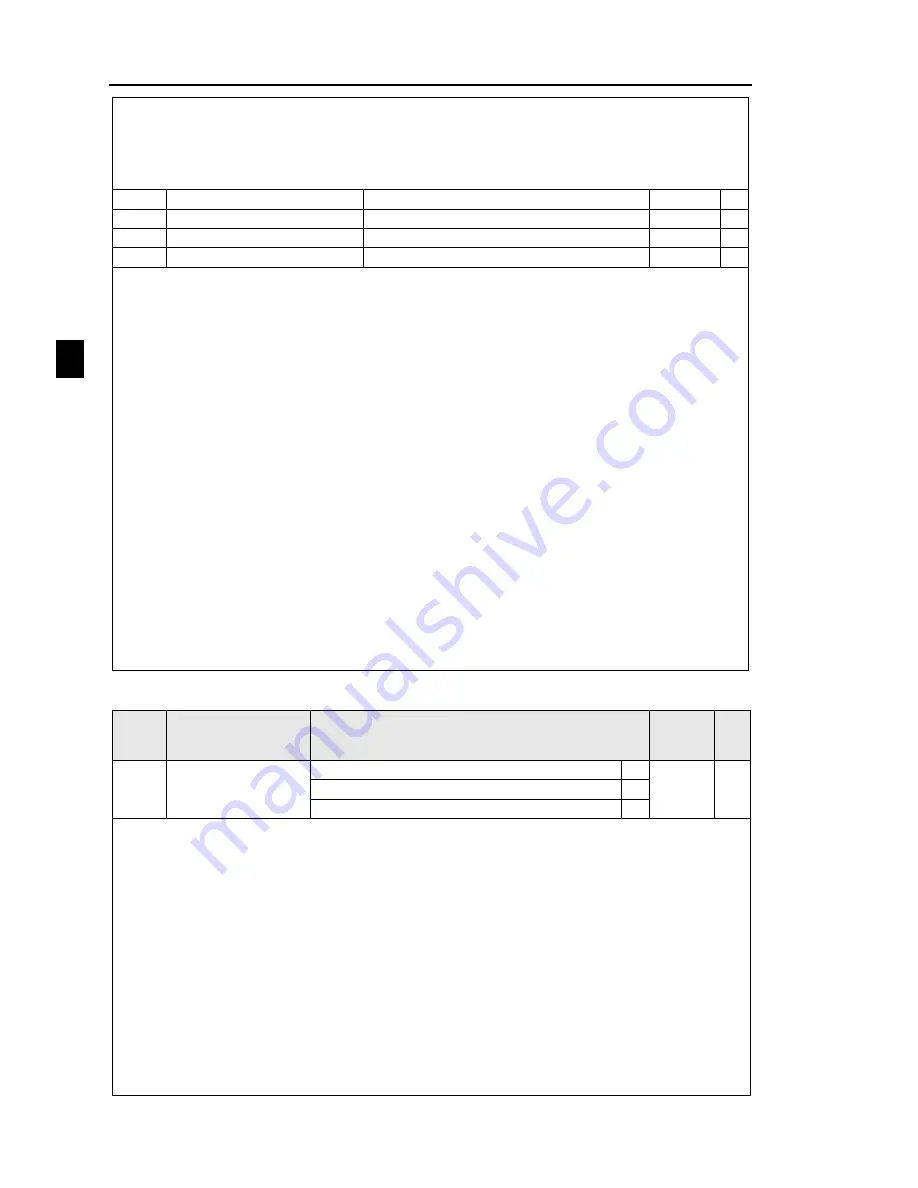

F2.16

DA1 zero bias coefficient

-100.0%~+100.0%

0.0%

☆

F2.17

DA1 gain

-10.00~+10.00

1.00

☆

F2.18

DA2 zero bias coefficient

-100.0%~+100.0%

0.00%

☆

F2.19

DA2 gain

-10.00~+10.00

1.00

☆

The above function codes generally used to bias the output amplitude of zero drift and

correcting the analog output. It can also be used to customize the desired analog output curve.

Calculation relationship with DA1 example:

y1 represents DA1 minimum output voltage or current value; y2 represents DA1 maximum

output voltage or current value

y1=10V or 20mA*F2.16*100%

;

y2=10V or 20mA*(F2.16+F2.17)

;

Factory Default F2.16 = 0.0%, F2.17 = 1, so the output 0 ~ 10V (or 0 ~ 20mA) corresponding

to characterize the physical minimum value to characterize the physical maximum.

Example 1:

0 ~ 20mA output will be changed to 4 ~ 20mA

The minimum input current value from the formula: y1 = 20mA * F2.16 * 100%,

4=20*F2.16, calculated according to the formula F2.16=20%

;

Maximum input current value by the formula:y2=20mA*(F2.16+F2.17)

;

20=20*(20%+F2.17),calculated according to the formula F2.17=0.8

Example 2:

0 ~ 10V output will be changed to 0 ~ 5V

The minimum input voltage value from the formula:y1=10*F2.16*100%

,

0=10*F2.16, calculated according to the formula F2.16=0.0%

;

The maximum input voltage value from the formula: y2=10*(F2.16+F2.17)

;

5=10*(0+F2.17),calculated according to the formula F2.17=0.5

5-2-5.

Start and stop control group

:

F3.00-F3.15

Code

Parameter name

Setting range

Factory

setting

Cha

nge

F3.00

Start-up mode

Direct startup

0

0

☆

Speed tracking restart

1

Pre-excitation start (AC asynchronous motor)

2

0: Directly startup

If the start DC braking time is set to 0, the inverter starts running from the start frequency. If

the start DC braking time is not set to 0, the inverter firstly performs DC braking and then starts

running from the start frequency. Applicable for the small inertia load and the application that the

motor may rotate when starting.

1: Speed tracking restart

The inverter firstly judges the speed and direction of motor, and then starts at the tracked

motor frequency, smoothly starts the rotating motor without shocks. Applicable for the momentary

power cut and restart with high inertia loads. To ensure the performance of Speed Tracking Restart,

it is required to accurately set the parameters of motor b0 group.

2: Asynchronous motor pre-excitation start

It is valid only for asynchronous motors, used to firstly create magnetic field before the motor

running. Please refer to the instructions of function code F3.05, F3.06 for pre-excitation current

and pre-excitation time

If the pre-excitation time is set to 0, the inverter will cancel the pre-excitation process, and