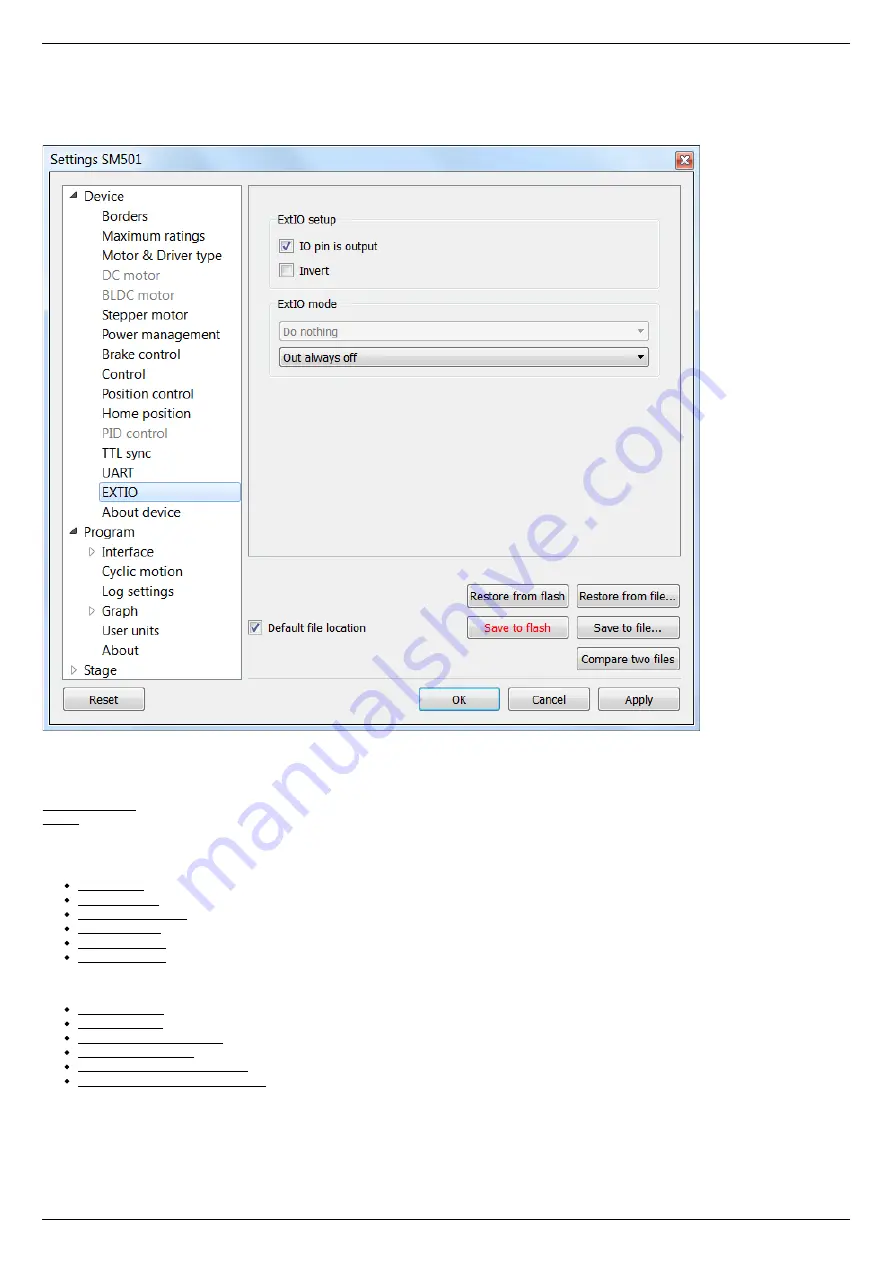

5.3.11. General purpose input-output settings

Device configuration -> EXTIO settings

General purpose input-output settings tab

For detailed information, please see

General purpose digital input-output

.

ExtIO setup

IO pin is output - if the flag is checked the needle of ExtIO works in output mode, otherwise - in the input mode.

Invert - if the flag is checked the rising edge is ignored and the falling edge is active.

ExtIO mode - mode selection

If ExtIO configured for input mode the choice of controller action settings by the input pulse is active:

Do nothing - do nothing.

Stop on input - run STOP command.

Power off on input - run PWOF.

Movr on input - run MOVR.

Home on input - run HOME.

Alarm on input - enter ALARM state.

If ExtIO configured for output mode the choice of the output state depending on the controller status is active:

Out always off - always in inactive state.

Out always on - always in active state.

Out active when moving - in active state during motion.

Out active in Alarm - in active state if the controller is in the Alarm state.

Out active when motor is on - in active state if the motor windings are powered.

Out active when motor is found - in active state if the motor is connected.

Page 144 / 345

Page 144 / 345

Summary of Contents for 8SMC5-USB

Page 30: ...Linux Page 30 345 Page 30 345 ...

Page 83: ...Connection of magnetic brake to one axis or two axis systems Page 83 345 Page 83 345 ...

Page 87: ...Scheme of buttons connection to the HDB 26 connector Page 87 345 Page 87 345 ...

Page 99: ...Page 99 345 Page 99 345 ...

Page 167: ...Vertical load capacity the maximum vertical load on the stage Page 167 345 Page 167 345 ...

Page 186: ...Click Next Click Continue anyway Page 186 345 Page 186 345 ...

Page 188: ...Page 188 345 Page 188 345 ...

Page 190: ...Page 190 345 Page 190 345 ...

Page 193: ...Page 193 345 Page 193 345 ...

Page 201: ...Select the XILab application in the Programs block Start it Page 201 345 Page 201 345 ...

Page 274: ...7 Files 1 Configuration files 2 Software Page 274 345 Page 274 345 ...

Page 331: ...Motorized Iris Diaphragms 8MID98 Motorized Iris Diaphragm Page 331 345 Page 331 345 ...

Page 338: ...8 Related products 1 Ethernet adapter Page 338 345 Page 338 345 ...

Page 339: ...8 1 Control via Ethernet 1 Overview 2 Administration Page 339 345 Page 339 345 ...