ZMC408SCAN Motion Controller Hardware Manual V1.5

3.

Please use STP, especially in bad environments, and make sure the shielding layer is

fully grounded.

5.2.

Basic Usage Method

1.

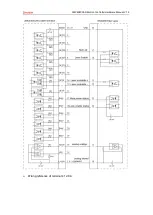

Please wiring correctly according to above wiring description.

2.

Please select one interface among EtherNET, RS232 (default parameters can be

directly connected) and RS485 (default parameters can be connected directly, need

to use adapter head for hardware) to connect ZDevelop.

3.

T

hrough “ZDevelop/In, Op window to operate and watch relative IOs.

4.

T

hrough “ZDevelop/AD/DA wi

ndow to operate and watch relative analog inputs and

outputs.

5.

In ZDevelop, send online command “PWM_FREQ (PWM No.) = frequency, PWM_DUTY

(PWM No.) = duty cycle.

Refer to BASIC routine:

B

ASE (4, 5) ‘select axis Scan 0, Scan 1 relates to

axis 6 and axis 7

A

TYPE = 21, 21 ‘select axis 4 and axis 5 as galvanometer axes type

U

NITS = 200, 200 ‘set pulse amount of axis 4, 5 as the unit of 200 bit

Dpos = 0, 0

Corner_Mode = 2, 2 ‘set axis corner deceleration mode is used fo

r corner delay

Decel_Angle = 30*PI/180, 30*PI/180

Stop_Angle = 90*PI/180, 90*PI/180

Z

smooth = 1000, 1000 ‘in galvanometer Scan instruction, Zsmooth is the max

delaying time 1000us when in corner delaying

F

orce_Speed = 100, 100 ‘in galvanometer Scan i

nstruction, Force_speed is axis 4/5,

and the Scan motion speed is 100*200 bit/s

M

oveScanAbs (0,0) ‘galvanometer moves to center origin position

Base (4, 5)

A

out (0) ‘set laser power is 50% for 12

-bit analog output 0, 0-10V

relates to 0-100% power.

O

p (29, ON) ‘open laser to enable IO