Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

21

Down Timer: #downTimer1 – #downTimer10

A numeric variable: The assigned value (using a

let

command) is decreased automatically (by msec).

You can assign another value during the countdown.

The maximum value that can be assigned is 2,147,483,647 (msec).

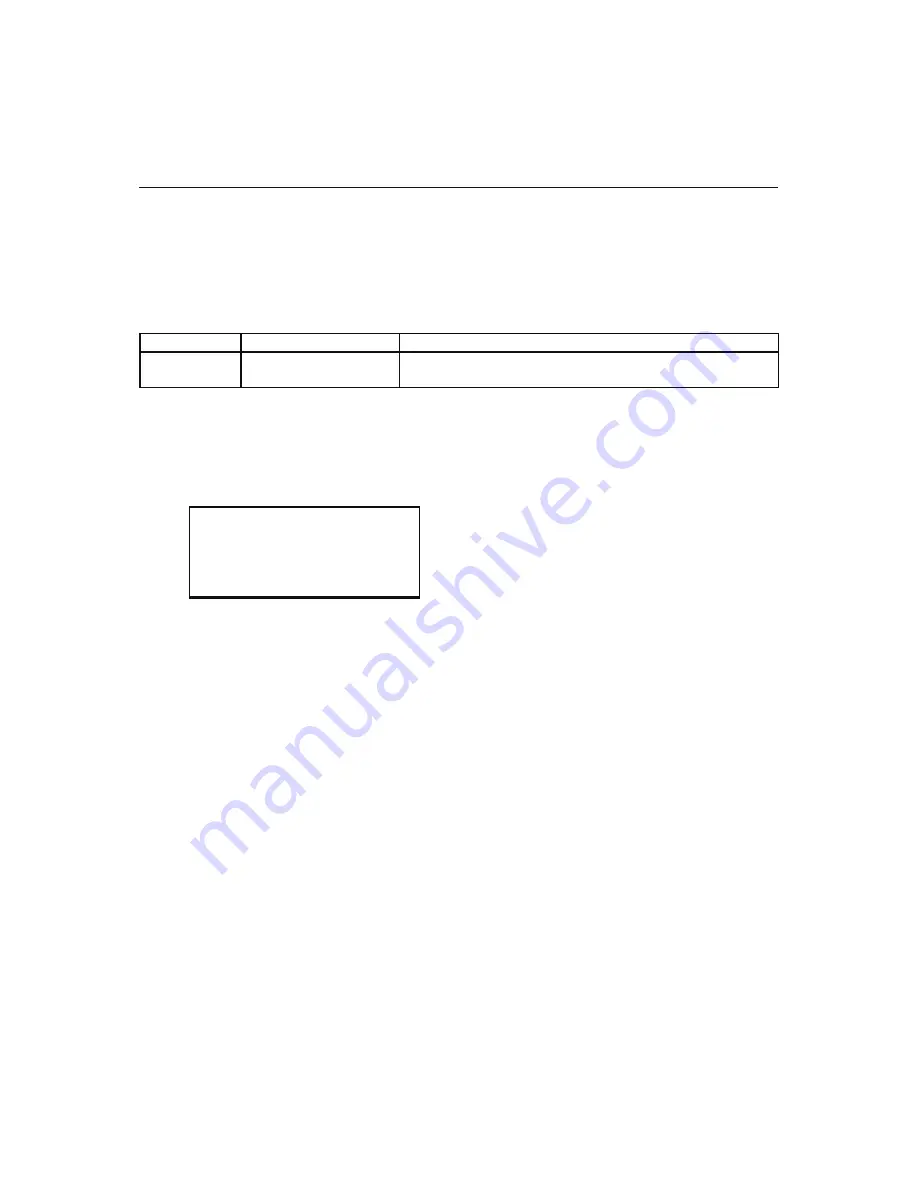

Category Identifier

Description

Special

Variable

#downTimer1 –

#downTimer 10

The assigned value is decreased automatically (by msec).

For example, create the following point job data and set it to a point as [Job while CP Moving]. The

hexadecimal

CR

code is output to COM2 every 0.5 seconds while it moves in the CP drive.

if

ld #downTimer1 == 0

then

eoutCOM port2,"%0D"

#downTimer1 = 500

If

#downTimer1

=

0

Then

Output a hexadecimal code

CR

from COM2 and

assign 500 (0.5sec) to #downTimer1.

z

In this case, you need to assign a value to #downTimer1 in advance (e.g. during a point job).