Page | 34

Option

Description

Labels

Custom

Universal Inputs.

Provides a set of 4 terminals that may be rewired internally to

suit customer specific applications, such as providing access to additional analog

inputs, terminals in parallel to an already available terminal (such as additional

SW12V, G or C1 connections), or for use with a customer supplied component. Two

terminals U1 and U2 are provided, with 2 additional power terminals

SW12V

G

U2

U1

Com Port Interfaces

RS485

Converts normal RS232 port into a RS485 serial port for use with 2-wire half duplex

instruments.

SW12V

G

RS485_B

RS485_A

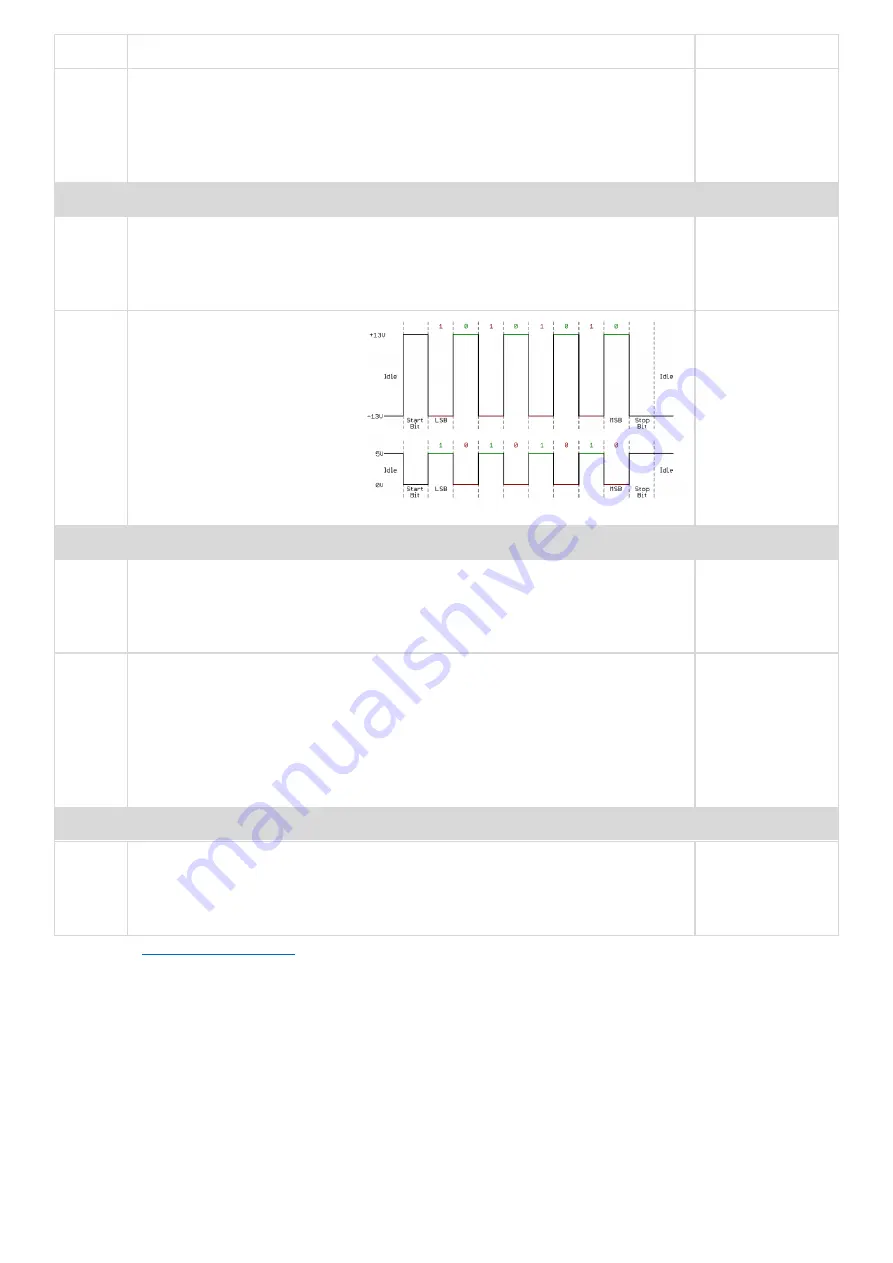

UART

Converts normal RS232 port into

a UART serial port for use with

instruments that require UART

voltage levels. RS232 voltages

are normally ±13V, while UART

voltages are normally 0-5V and

inverted. The four-terminal

provided are Tx, Rx, SW12V and

G.

SW12V

G

Tx

Rx

Power Output Peripherals

Power

Switch

The power switch provides 3 high current outputs from the normally low power

outputs A3, A4 and PSW. Inside the electronics housing are 3 x 5V regulators with

an output current up to 800mA. 4 terminals are provided, one each for the boosted

A3, A4 and PSW outputs and an additional Ground (G)

A3

A4

PSW

G

Relay

Output

The relay output peripheral provides two independently controlled dry contact

switch outputs from the A3 and A4 outputs. Each relay output is a separate pair of

Common (C) and Normally Open outputs. For example, a relay connected to A3

input has the common terminal wired to A3+ and the normally open terminal wired

to A3-. Similarly, the relay connected to A4 has its own common terminal wired to

A4+ and the normally open terminal to A4+. While the relay is rated to 8A, the

contacts should only be used for up to 2A due to the wire sizes used internally.

A3+

A3-

A4+

A4-

Miscellaneous

EXO SOA The electronics housing may include an EXO Signal Output Adapter (SOA) to convert

the proprietary EXO signal to an SDI12 output. This port connects to the same

labelled ports on the SOA. Refer to the EXO SOA documentation for further details.

RED

BLACK

YELLOW

WHITE

Refer to the

for more detailed specifications on the I/O and program functionality.

4.1.5

Internal Status Sensors

The Ai1 provides extensive internal status monitoring to help diagnose operational problems remotely. All status

sensors are read periodically (SLOW_MEASUREMENT_INTERVAL) or can be manually triggered by setting

ReadStatusSensors to True.

Humidity

The humidity sensor indicates if the internal desiccant is still effective or needs replacement. The humidity reading is

viewed from the

InternalHumidity

public variable or the logged data. The internal humidity measurement is

indicative (±8%) and anything over 80% is likely to have internal condensation. It is critical that internal humidity be

monitored and alarmed as internal condensation can cause significant

damage that is not covered by warranty. Internal humidity is managed

Figure 14 - Orange (dry), Green (moist)