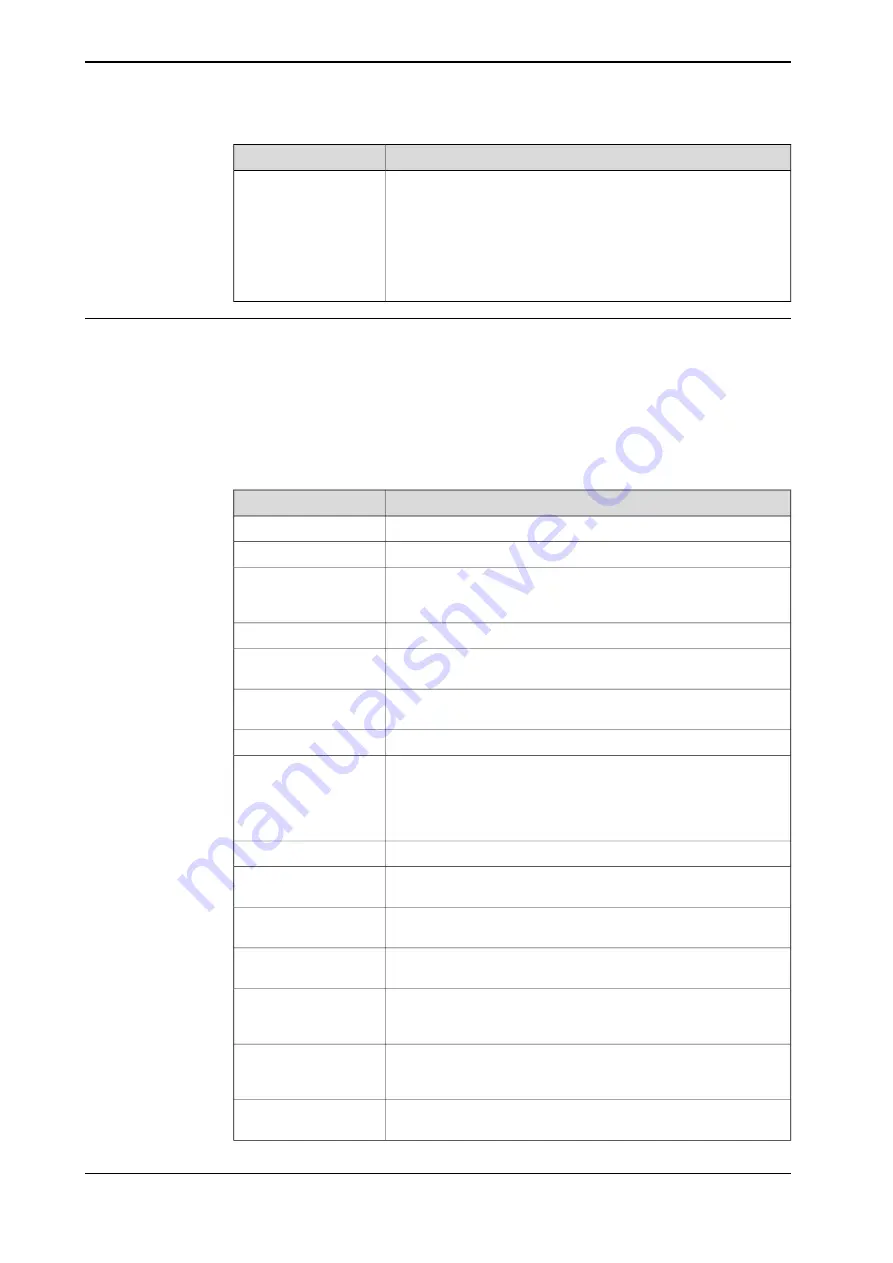

Description

Routine

Does the same as PickPartAtCamera with the addition that it also

can handle to pick multiple parts from one image.

FUNC num PickMulti-

PartsAtCamera(num

CameraNumber,\num

NumberOf-

PartsToPick,\num De-

siredPositions{*},\num

MaxImageRetries,\num

TimeoutTimeVision)

PartCam1.mod

PartCam1.mod is always supplied with FlexLoader Vision. It handles the part

specific programming, e.g. loading, unloading, marking, air cleaning.

Two example modules are delivered, one for operation with simplified TeachIn

(FlexLoader Vision Lite) which is named LitePartCam1.mod, the other for standard

operation with standard TeachIn. Refer to chapter on robot program.

Standard functionality

Description

Routine

Template routine for the air cleaning option.

PROC AirCleanDetail()

Template routine for the deburring unit option.

PROC DeburrDetail()

Part specific handling routine for camera 1 depending in which

position FlexLoader Vision identified the part. Note, this routine

is not always used in the example routines.

PROC Cam1Posi-

tion_n()

Initializes the camera and part specific data.

PROC InitializeCam1()

Leaves a part on an out belt.

PROC LeaveFeed-

er_OUT()

Template routine for the statistical outlet option.

PROC LeaveSampleOut-

let()

Loads a part into the machine, multiply routine if several machines.

PROC LoadMachine()

Handles the main flow of the cell together with main(). This include

to check status of machines and so on to figure out what to do

next. All these kind of selections and checks that are part specific

is placed in this routine. The rest is placed in either of the routines

depending on how the integrator wants the structure.

PROC MainRoutine1()

Template routine for the marking unit option.

PROC MarkDetail()

Moves robot to control image position. Only used if need of second

control image.

PROC MoveToCon-

trolImage()

Moves robot from control image position. Only used if need of

second control image.

PROC MoveFromCon-

trolImage()

This routine performs the actual picking of a part from the conveyor

at camera position.

PROC PickCam_1()

This routine does the same as PickCam_1 but for the case of

picking multiple parts from one image.

PROC PickMultiParts-

Cam_1(num

PartNo,num Position)

This routine is called to approach an intermediate position towards

the conveyor before picking. Update this position to suite the

current application.

PROC RefPosInCam_1()

This is an intermediate position used when leaving the picking

area. Update this position to suite the current application.

PROC RefPosOut-

Cam_1()

Continues on next page

202

Product manual - FlexLoader SC 6000

3HAC051768-001 Revision: D

© Copyright 2014-2020 ABB. All rights reserved.

F FlexLoader RAPID reference

F.3 FlexLoader application functionality

Continued

Summary of Contents for FlexLoader SC 6000

Page 1: ...ROBOTICS Product manual FlexLoader SC 6000 ...

Page 8: ...This page is intentionally left blank ...

Page 12: ...This page is intentionally left blank ...

Page 78: ...This page is intentionally left blank ...

Page 172: ...This page is intentionally left blank ...

Page 174: ...This page is intentionally left blank ...

Page 176: ...This page is intentionally left blank ...

Page 178: ...This page is intentionally left blank ...

Page 182: ...This page is intentionally left blank ...

Page 184: ...This page is intentionally left blank ...

Page 186: ...This page is intentionally left blank ...

Page 192: ...This page is intentionally left blank ...

Page 224: ...This page is intentionally left blank ...

Page 283: ......