67

interpretation of the electronic gear.

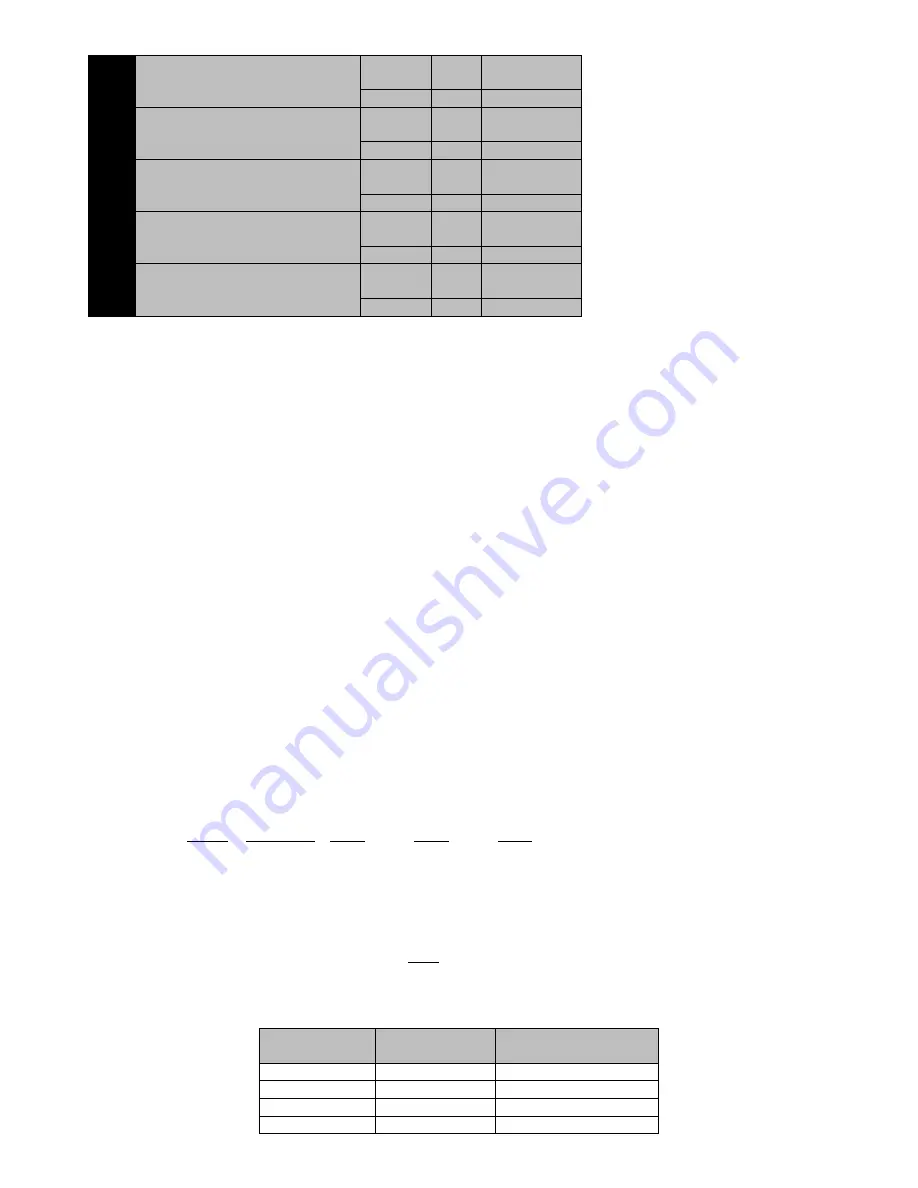

P1-27

Electronic gear numerator 1

Initail value

Unit

Communication

Address

1

-

211BH

P1-28

Electronic gear denominator

Initail value

Unit

Communication

Address

1

-

211CH

P1-29

Electronic gear numerator 2

Initail value

Unit

Communication

Address

1

-

211DH

P1-30

Electronic gear numerator 3

Initail value

Unit

Communication

Address

1

-

211EH

P1-31

Electronic gear numerator 4

Initail value

Unit

Communication

Address

1

-

211FH

Control Mode

:

P

Range

:

1~65535

Data size

:

16bit

Display mode

:

Decimal system

Parameter function

:

P1-26~P1-31used to set electronic gear ratio.

Electronic gear ratio

It can be easily match with all kinds of pulse source through setting electronic gear ratio under position control mode, in order to achieve the

ideal control resolution ( the Angle/pulse).

Electronic gear ratio set way

:

①

Set electronic gear ratio factor

P1-26

。

Set

electronic gear ratio factor

mainly depend on the type of the encoder motor used.

The parameter must be 0 when motor used 2500ppr incremental encoder.

The parameter must be 17 when motor used17bit encoder,

it

shows that 131072 pulse encoder feedback in per circle. Also set

another nonzero value, it depends on

the calculation results of electronic gear ratio.

②

Calculate the desirable electronic gear ratio

G

:

Electronic gear ratio

;

P

:

The number of input instructions‘ pulse

;

N

:

Motor rotation laps

;

C

:

The encoder line number, if encoder is 2500ppr incremental, then C

=

10000

(

After four times the frequency

)

If encoder is 17bit encoder, then C=131072.

③

It needn’t get a specific number about calculation of electronic gear ratio G, just make

numerator and denominator divided by

common divisor, the value of numerator and denominator can meet parameter Range as far as possible.

For example

:

Case1

:

motor uses 2500ppr encoder

,

when input instruction is 6000 pulses

,

servo motor rotate one circle

:

Because of 2500ppr encoder

,

P1-26 must be 0.

Electronic gear numerator and

denominator can be set

:

Setting way I

:

P1-27=100

,

P1-28=60

Setting way II

:

P1-27=10

,

P1-28=6

Setting way III

:

P1-27=5

,

P1-28=3

Case2

:

motor uses 17bit encoder, when input instruction is 5600 pulses, servo motor rotate one circle

:

17

16

15

1 131072

1

2

1

=

=

=

5600

5600

5600

1400

2

2

2

N

C

G

P

The parameters can be set

:

Setting way I

:

P1-26=17

,

P1-27=1

,

P1-28=5600

Setting way II

:

P1-26=16

,

P1-27=2

,

P1-28=5600

Setting way III

:

P1-26=15

,

P1-27=1

,

P1-28=1400

④

Electronic gear ratio for the recommended range

(

when uses 2500ppr encoder

)

1

1000

1000

G

⑤

When it need switching frequently among the different electronic gear ratio, it can modify P1-27

、

P1-28 by communication mode

online; also can by setting two DI terminals for 20 (GNUM0) and 21 (GNUM1) function, then to switch through external DI input. at this

time, the corresponding electronic gear numerator as shown below

:

GNUM0

GNUM1

Effective electronic gear

numerator

0

0

P1-27

0

1

P1-29

1

0

P1-30

1

1

P1-31