Bringing the Benefits of Real-Time Data Collection to the World

Sutron Corporation, Tel: 703-406-2800,

http://www.sutron.com

40

each output. This is especially important for sensors that take a significant time to measure

(imagine taking 5 separate measurements to obtain 5 parameters from an SDI sensor that takes

30 seconds to measure!). In addition, for some sensors, it may be important to ensure parameters

were measured at the same time.

To ensure only one measurement is made for all outputs of a single sensor,

the I/O device

configuration for each sensor entry representing a separate output, must be the same

. The

I/O device configuration consists of different parameters for different types of sensors. If the

sensor reads an analog input, then the analog input’s module and channel must be the same. If

the sensor reads a com port to obtain its input, then the com port must be the same. For SDI-12

sensor’s, the SDI-12 address and command must be the same. Note: the I/O device configuration

must be set the same

when creating the sensor entry

. Changing the configuration to be the

same after the entry has been made, does not result in “linking” any outputs.

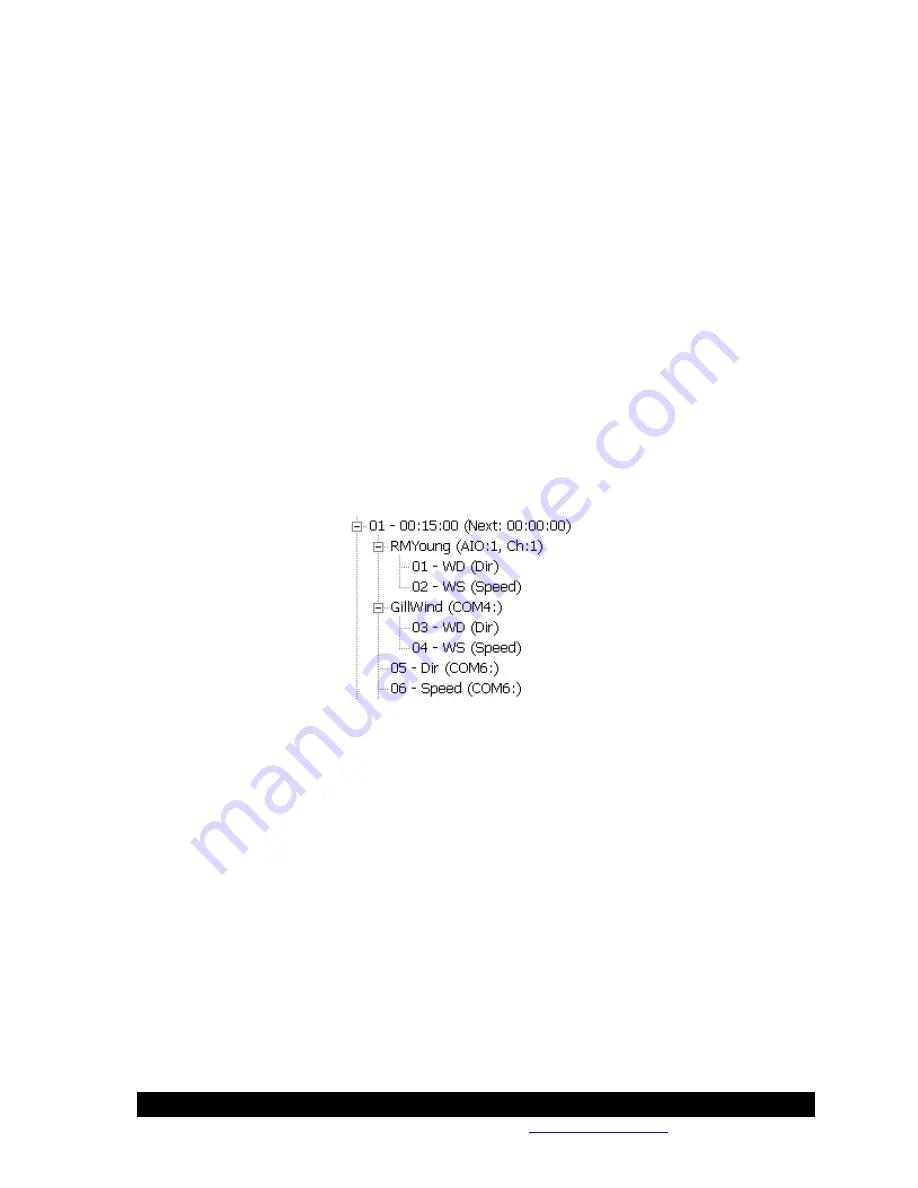

In the example below, the Dir and Speed outputs of the RMYoung sensor are linked. One

measurement of the sensor will be made every 15 minutes to obtain both values, Dir and Speed.

The same is the case for the GillWind sensor on COM4. However, the GillWind sensor on

COM5 does not have its outputs linked. This would happen if, for example, the Speed sensor

entry was created with the selection of COM7 and then changed to COM6 to match the Dir

entry.

Once outputs are linked,

a change to one will affect all linked outputs

. Using the above as an

example, if you select the GillWind Dir entry and change its com port to COM3, it will change

for the Speed setting as well.

Once an output has been linked, you must delete the entry to “unlink” it. Hence, to fix the fact

that the Speed output of the GillWind sensor on COM6 is not linked to the Dir output, you would

first delete the Speed entry, and then re-add it, making sure to set the com port setting to COM6

in the process.

Event Driven Sensors

The vast majority of sensors measure when told to, i.e., according to the measurement schedule

you define. The exception to this rule occurs when using a sensor with an

Event

option checked

(like BinIn). Every time an

Event

occurs, the entire set of sensors defined under the measurement

schedule will be measured. For example, if you had an EZSetup measurement schedule with the

BinIn block (

Event checked)

and an sdi-12 sensor, every time the BinIn detected a change of

state, the SDI-12 sensor would also be measured.

Summary of Contents for Xpert2

Page 2: ......

Page 11: ...Chapter 1 Introduction...

Page 16: ......

Page 17: ...Chapter 2 Getting Started...

Page 86: ......

Page 87: ...Chapter 4 Graphical Setup Diagrams...

Page 104: ......

Page 105: ...CHAPTER 5 EXAMPLE SETUPS...

Page 128: ......

Page 129: ......

Page 130: ......

Page 131: ...Chapter 7 Installation...

Page 140: ......

Page 141: ...Chapter 8 Maintenance and Troubleshooting...

Page 145: ...Appendix A Setup Blocks...

Page 266: ......

Page 267: ...Appendix B Updating the Firmware...

Page 290: ......

Page 291: ...Appendix E Software Development Kit SDK...

Page 293: ...Appendix F Creating Custom Voice Files...

Page 330: ......