incremental position based on the original position, this value will be the target position.

●

when it is running, to modify the value in register

(

60*(N-1)

)

can real-time change

the absolute target position. The instruction will move to the modified target position then stop.

For example: the target position is 1000, it runs to position 600.

(1)

Change (60*(N-1)) to 400 or -400, axis S3 forward decelerate until stop, then

reverse accelerate to the position 400 or -400 and decelerate to stop. At this time change

(60*(N-1)) to 1200, axis S3 will forward run to position 1200 and decelerate to

stop.

●

servo enable, the speed register (60*(N-1)) value is 1000, when M0 from OFF to ON,

(60*(N-1)) change to S1 value.

When the motor is running, modify (60*(N-1)) can change the real-time speed, motor

will change to new speed with setting acceleration/deceleration time.

If the speed is 0, the motor will stop with deceleration time. As the speed become 0 before

reaching the target position, the motion complete flag (20*(N-1)) will not reset. At this

time, set new speed in (60*(N-1)), the motor will run again.

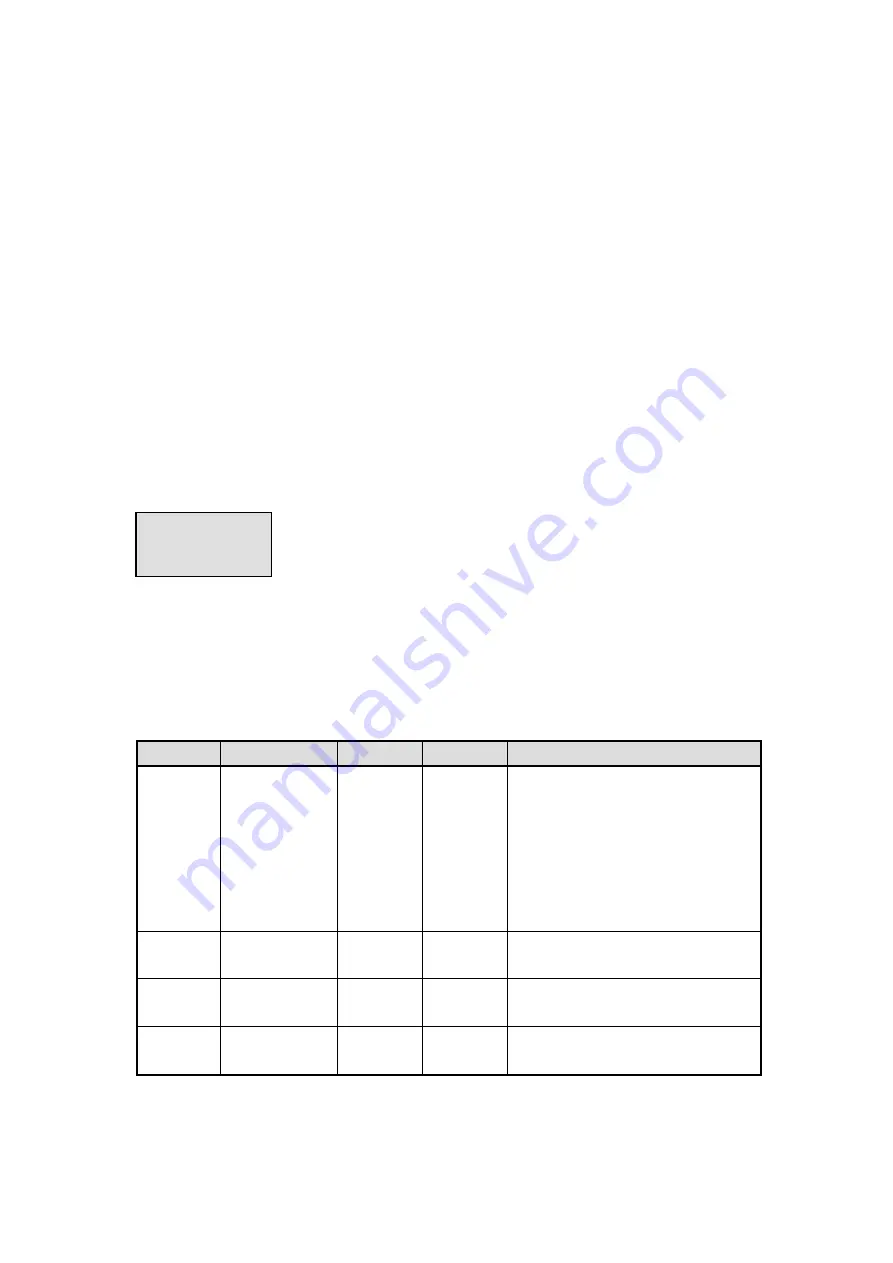

After PLC is running, servo is enable, modify SD register can change the target absolute position,

speed and other pararmeters, the parameters will be effective after 6~16ms. One motion filedbus

can connect 10 axes, the axis no. is 1 to 10. Please see the parameters of each axis in the following

table.

Table 1: set parameters (N=1~10)

Address

Defintion

Type

Unit

Remark

60*(N-1)

Absolute

position

32-bit

integer

Pulse

numbers

Coordinate position is calculated

from target position setting pulse

numbers. Modify the position when

stop or running, it will move toward

the setting position with setting

speed. The setting position is

absolute position.

60*(N-1)

Speed

32-bit

integer

Pulse/seco

nd

60*(N-1)

Acceleration

time

32-bit

integer

ms

The time Accelerating from 0 max

speed

60*(N-1)

Deceleration

time

32-bit

integer

ms

The time decelerating from max

speed to 0

Table 2: state bit (N=1~10)

Related register