(20*(N-1)) will change.

●

when the motor enabled, it can clear the parameters in table 1 and 2.

●

there are four methods to change the present position:

①

return to origin through (20*(N-1)), (20*(N-1)), the present

position will change.

②

when PLC stop, modify the target position feedback pulse numbers (+20*(N-1)), the

present position will change

③

when PLC is running, execute MOWRITE can modify (20*(N-1)), the

present position will change.

④

when PLC is running, servo does not enable, the servo position is chagned by

external force, register (20*(N-1)) will change. When the servo enabled, this value is

valid.

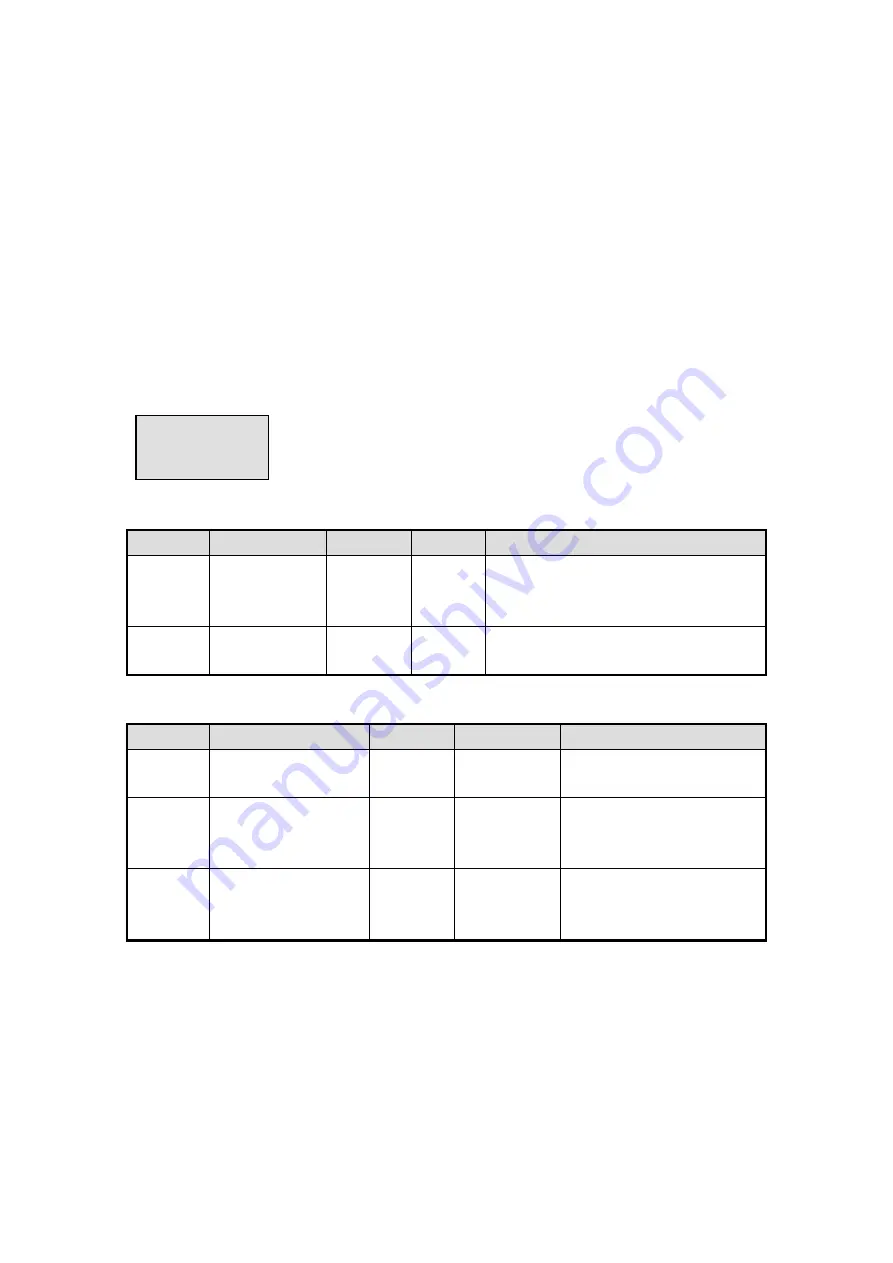

Table 1: state quantity parameters (N=1~10)

Address

Definition

Type

Unit

Mark

60*(N-1)

Present

displacement

quantity

32-bit

integer

Pulse

number

The displacement relative to the last stop

position

60*(N-1)

Present

position

32-bit

integer

Pulse

number

The coordinate position, calculated from

target position feedback pulse numbers

Table 2: self preserving state (N =1~10)

Address

Definition

Type

Unit

Mark

20*(N-1)

Target position setting

pulse numbers

64-bit

integer

Encoder

count

Relative zero position

20*(N-1)

Target

position

feedback

pulse

numbers

64-bit

integer

Encoder

count

Relative zero position

20*(N-1)

Present displacement

pulse numbers

64-bit

integer

Encoder

count

Single

time

motion

instruction

displacement

quantity

Related register