7.

Click “write config”. It will show the write in successful window.

8.

Click confirm, restart the PLC again to make the configuration effective.

Note:

(1)

When the device is changed, please configure again.

(2)

Please run the XINJE config as administrator for the PC system higher than win7.

(3)

Please close the antivirus software when using the XINJEconfig.

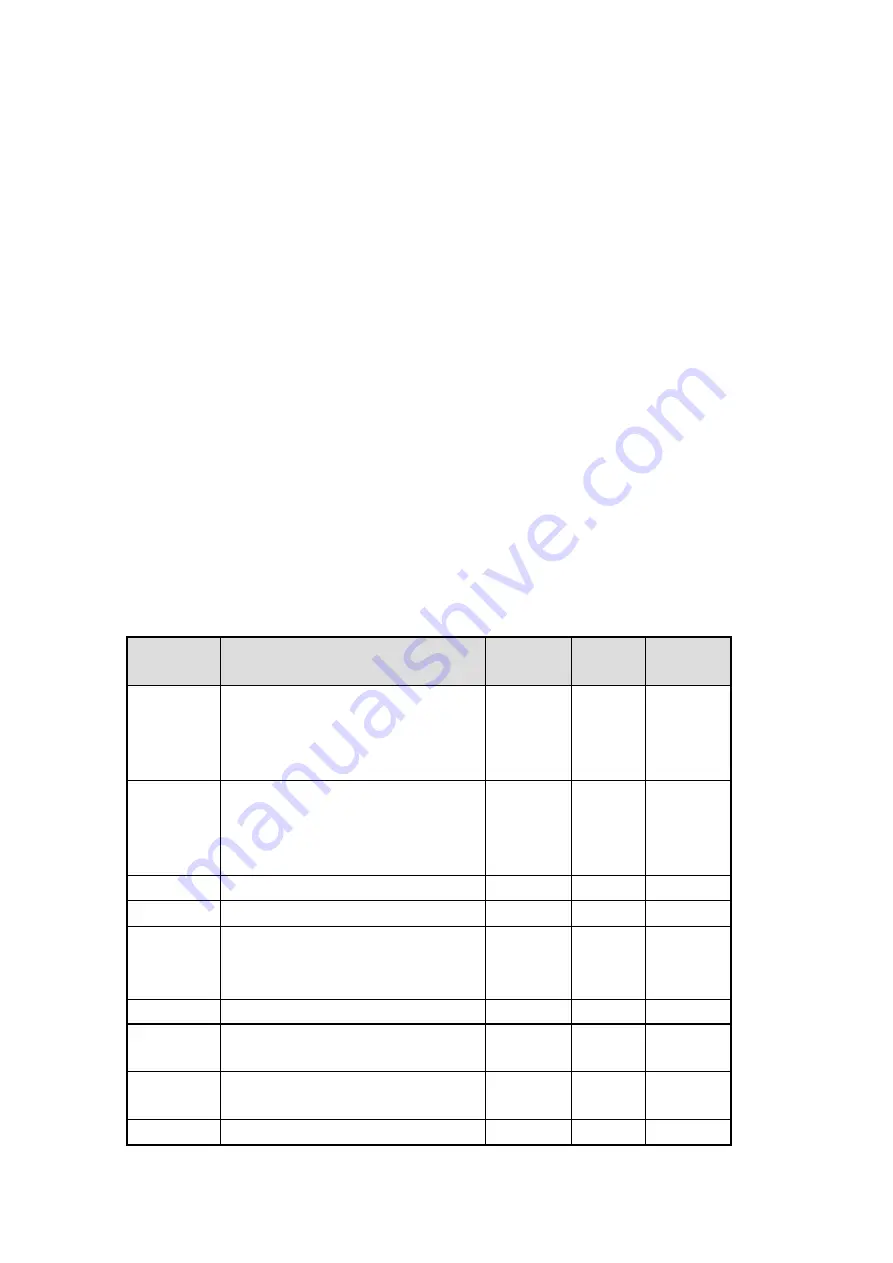

Appendix 2 Servo parameters

It needs to set the servo drive parameters before debugging the program. The fieldbus parameters

are shown as the following.

1.

Parameters

10-axis and down(include 10-axis): change the default value to suitable value for parameter P0-01,

P0-03, P7-00, P7-01, P7-02.

10-axis to 20-axis: change the default value to suitable value for parameter P0-01, P0-03, P7-00,

P7-01, P7-02, P7-05, P7-07.

Servo

parameter

Functions

Default

value

10-axis

value

20-axis

value

P0-01

Control mode 1

8: fieldbus torque mode

9: fieldbus speed mode

10: fieldbus position mode

6

10

10

P0-03

Enable mode

1: IO enable

2: software enable

3: fieldbus enable

1

3

3

P7-00

RS485 station no.

1

1~10

1~20

P7-01

RS485 serial port parameters

0x2206

0x2213*

0x2213*

P7-02

RS485 communication protocol

1: Modbus

2: simple XNet

1

2

2

P7-03

Sampling time (unit: character)

9

--

--

P7-04

Slave

station

space

time

(unit:

character)

15

--

--

P7-05

Slave station quantity

1~10

10

--

20

P7-06

Retry times

10

--

--