Fieldbus control through a fieldbus adapter 409

Basics of the fieldbus control interface

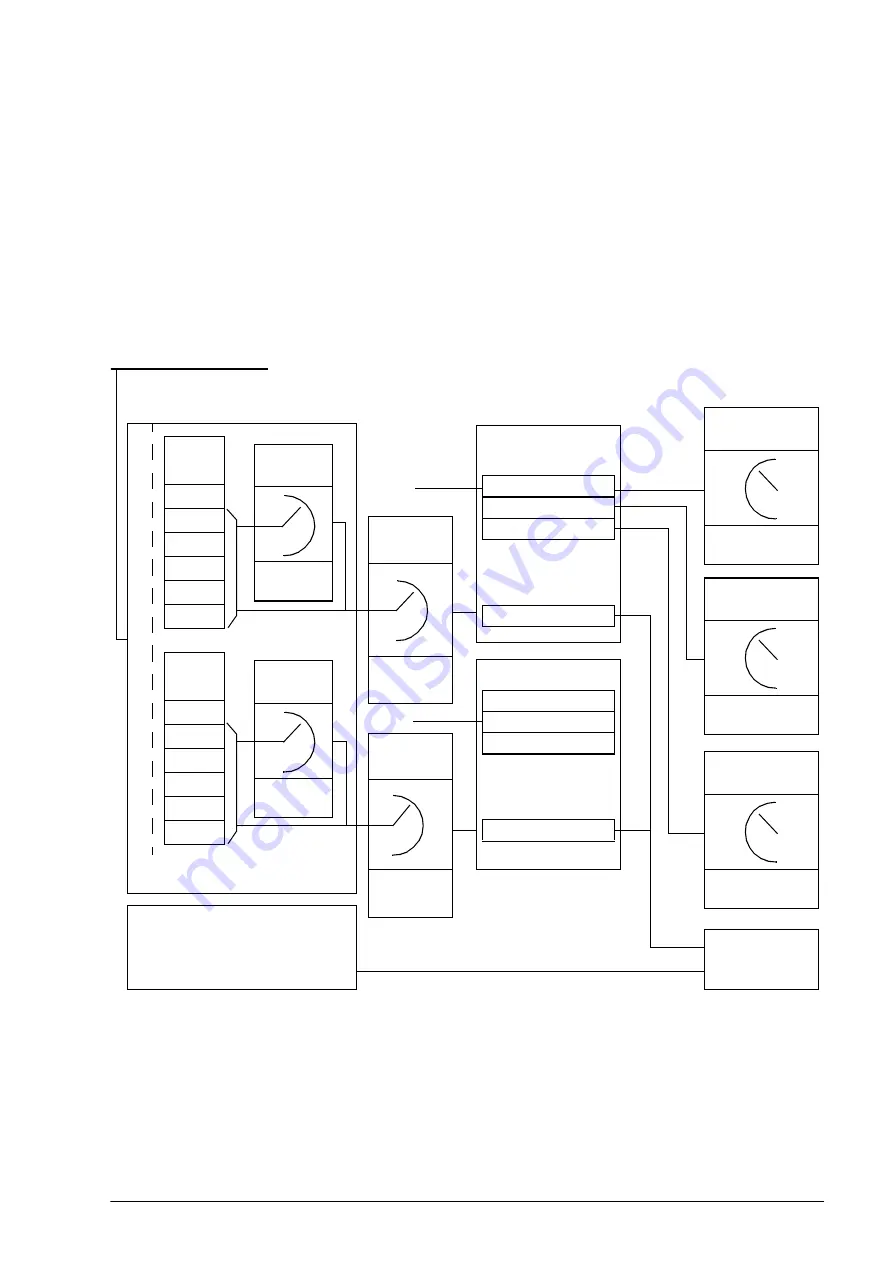

The cyclic communication between a fieldbus system and the drive consists of 16- or

32-bit input and output data words. The drive is able to support a maximum of 12 data

words (16 bits) in each direction.

Data transmitted from the drive to the fieldbus controller is defined by parameters

…

. The data transmitted from the

fieldbus controller to the drive is defined by parameters

.

DATA

OUT

2)

4)

1

2

3

…

12

DATA

IN

2)

5)

1

2

3

…

12

FBA MAIN SW

FBA ACT1

FBA ACT2

Par. 01.01…99.99

FBA MAIN CW

FBA REF1

FBA REF2

Par. 10.01…99.99

1) See also other parameters which can be controlled from fieldbus.

2) The maximum number of data words used is protocol-dependent.

3) Profile/instance selection parameters. Fieldbus module specific parameters. For more

information, see the

User’s Manual

of the appropriate fieldbus adapter module.

4) With DeviceNet, the control part is transmitted directly.

5) With DeviceNet, the actual value part is transmitted directly.

3)

3)

Parameter

table

4)

5)

1)

Fieldbus network

Fieldbus adapter

F

iel

dbu

s-

spec

ifi

c

int

erf

a

ce

Profile

selection

Profile

selection

DATA OUT

selection

Group 53

DATA IN

selection

Group 52

FBA Profile

EXT1/2

Start func

Speed/Torque

REF1 sel

/

Speed/Torque

REF2 sel

/

Cyclic communication

Acyclic communication

See the manual of the fieldbus

adapter module.

Summary of Contents for ACS860

Page 1: ... ABB INDUSTRIAL DRIVES ACS860 primary control program Firmware manual ...

Page 4: ......

Page 10: ...10 Table of contents ...

Page 18: ...18 Using the control panel ...

Page 24: ...24 Control locations and operating modes ...

Page 54: ...54 Program features ...

Page 78: ...78 Program features ...

Page 90: ...90 Application macros ...

Page 342: ...342 Additional parameter data ...

Page 380: ...380 Fault tracing ...

Page 381: ...Fault tracing 381 ...

Page 382: ...382 Fault tracing ...

Page 436: ...436 Control chain diagrams ...