The module contains a number of predefined procedures or functions for

communication with the machine tool:

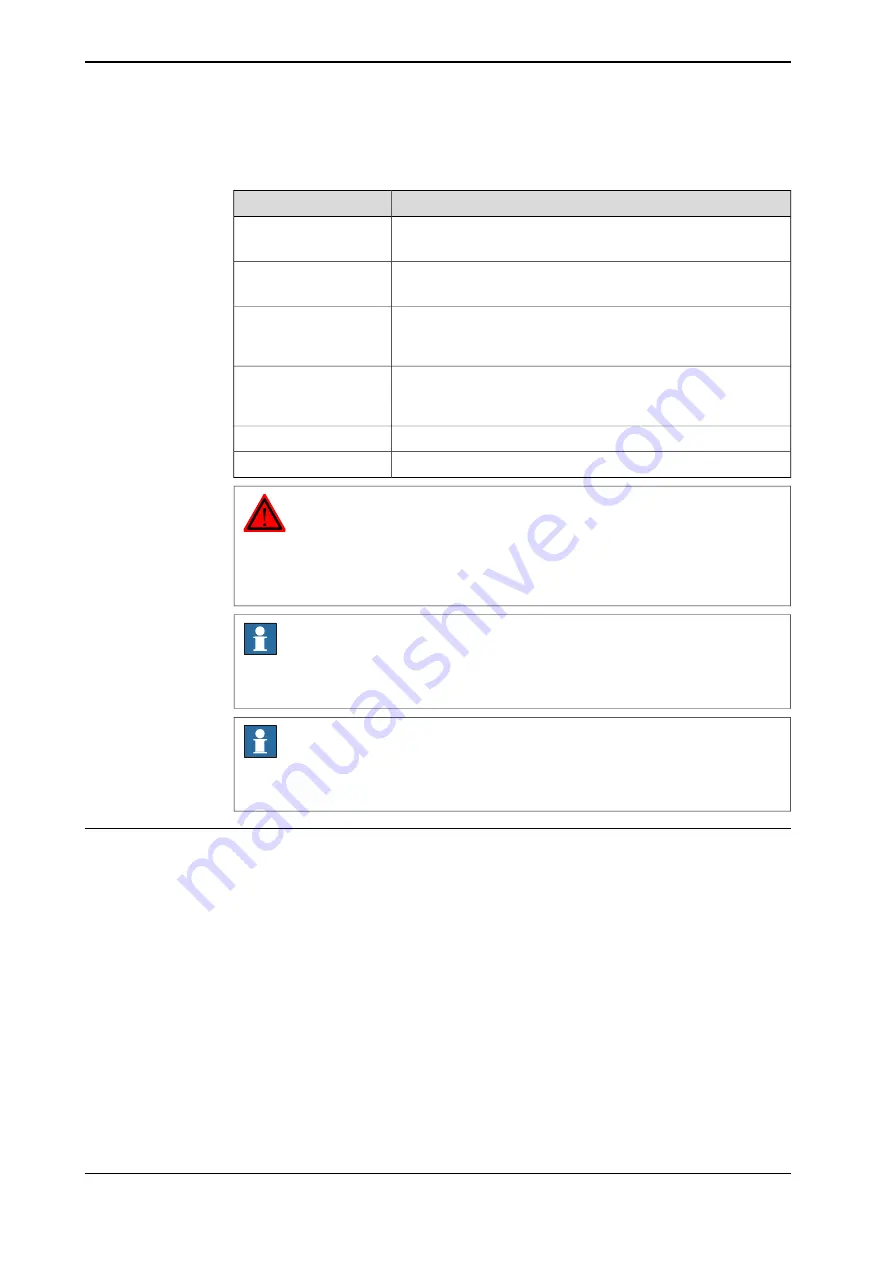

Description

Name

Initiates what is necessary for machine handling. Sets up traps.

PROC InitMachine

NEEDED: Set up correct signals for interrupt handling.

Performs desired machine tool action.

PROC Machine1Action

(string sAction)

NEEDED: Define signals and communicate with machine tool.

Checks machine tool and conditions and returns correct state

for use in main flow of program.

FUNC bool Ma-

chine1Check (string

sCheck)

NEEDED: Define signals and communicate with machine tool.

Waits for machine condition to be ok within

nMaxTime

. Returns

false if

nMaxTime

elapses.

FUNC bool Ma-

chine1Wait (string

sWait,num nMaxTime)

NEEDED: Define signals and communicate with machine tool.

Support routine for calibration of a lathe main chuck.

PROC CalibMainChuck

Support routine for calibration of a lathe sub chuck.

PROC CalibSubChuck

DANGER

Ensure that the standard features in

Machine1Action

,

Machine1Check

and

Machine1Wait

are correctly implemented. Malfunction and collisions might

otherwise occur.

Note

We recommend the use of an additional background task if the robot cell requires

time critical machine tool communication.

Note

Operation with more than one machine requires the creation of these routines

with equivalent names, e.g. Machine2Action and Machine3Wait.

States and actions

This module uses a number of predefined states and actions that are consistently

used. If needed, new values can be added in GlobalCodeAndConfig.sys. However,

do not remove the existing values, as these are used in the FlexLoader core

functionality.

Examples for predefined values are:

•

Examples for predefined machine checks/waits:

DOOR_OPENED, PREPICK_OK, LOAD_SUB_OK, LOAD_MAIN_OK,

UNLOAD_SUB_OK, UNLOAD_MAIN_OK, HOME_POSITION_OK,

MAIN_CHUCK_OPENED, MAIN_CHUCK_CLOSED, SUB_CHUCK_OPENED,

SUB_CHUCK_CLOSED

•

Examples for predefined machine actions:

CLOSE_CHUCK_MAIN, CLOSE_CHUCK_SUB, CLOSE_DOOR,

OPEN_CHUCK_MAIN, OPEN_CHUCK_SUB, OPEN_DOOR,

Continues on next page

284

Product manual - FlexLoader Vision

3HAC051771-001 Revision: B

© Copyright 2014-2018 ABB. All rights reserved.

B FlexLoader RAPID reference

B.7 FlexLoader machine tool interface functionality

Continued

Summary of Contents for FlexLoader Vision

Page 1: ...ROBOTICS Product manual FlexLoader Vision ...

Page 8: ...This page is intentionally left blank ...

Page 12: ...This page is intentionally left blank ...

Page 14: ...This page is intentionally left blank ...

Page 16: ...This page is intentionally left blank ...

Page 62: ...This page is intentionally left blank ...

Page 96: ...This page is intentionally left blank ...

Page 180: ...This page is intentionally left blank ...

Page 218: ...This page is intentionally left blank ...

Page 286: ......

Page 287: ......