Cryo-con Model 24C

Front Panel Menu Operation

Sensor Setup Menu

The Sensor Setup menu is used to view and edit user temperature sensor data.

The Sensor Header Edit Menu

Pressing the

Sensor

key from the Home Status Display accesses the Sensor Setup

Menu. From there, the Sensor Header Edit Menu can be accessed by by scrolling to

the sensor and pressing

Enter

.

Definition of a sensor requires entering configuration data on this screen followed by

entering a calibration curve.

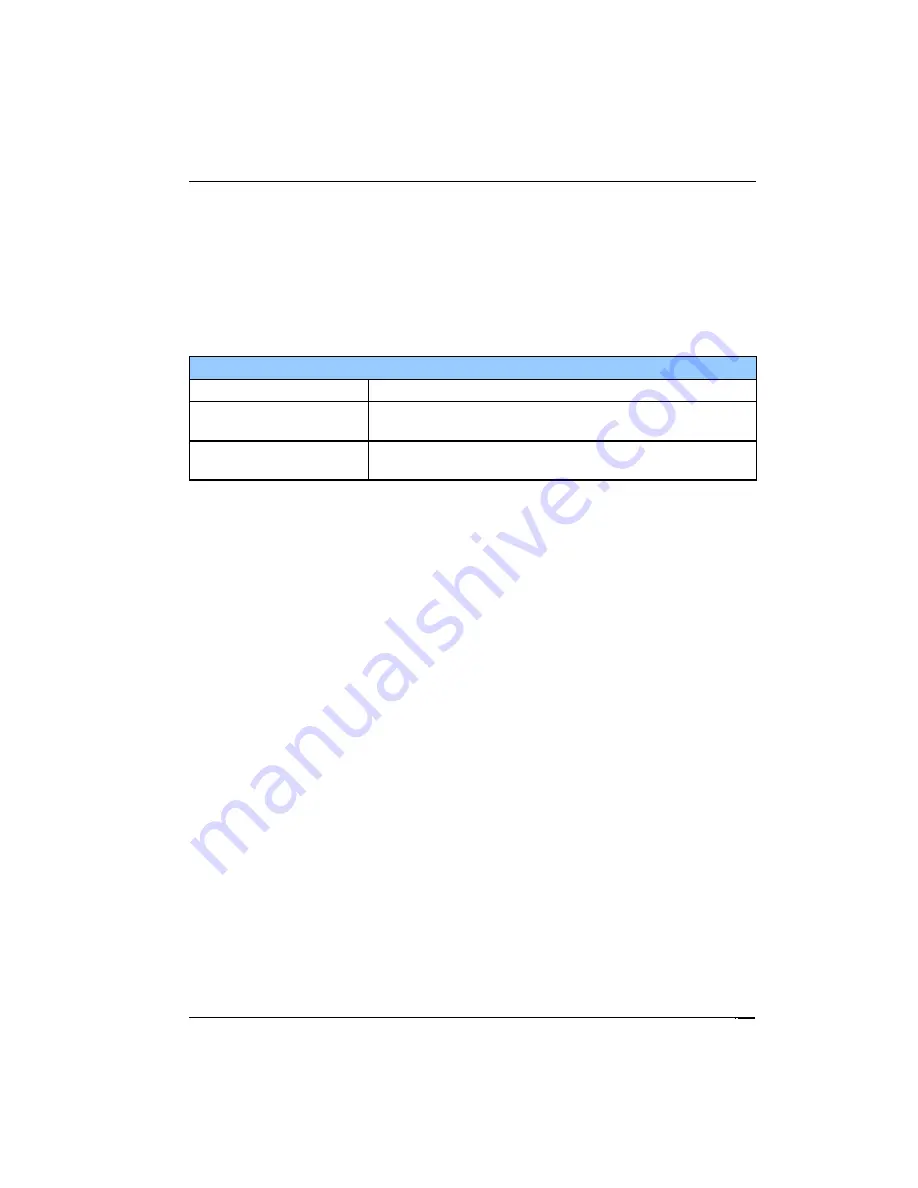

Sensor Header Edit Menu

+

Sets the Sensor Type.

#

Sets the sensor Temperature Coefficient and Calibration

Curve Multiplier.

+

Sets Units of the sensor’s Calibration Curve. Choices

are: Ohms, Volts and LogOhm.

Table 24: Sensor Setup Menu

The first line on this menu is the sensor table index. Selecting this field allows the

user to scroll through all of the sensors configured in the unit, including user sensors.

The index is displayed along with the sensor name.

Note: the sensor name may be entered via any of the Remote I/O interfaces, but may

not be changed from the front panel.

Sensor Type is an enumeration of all of the basic sensor types supported by the

Model 24C. Choices are shown in the

Supported Sensor Configurations

table above.

The

Multiplier

field is a floating-point numeric entry and is used to specify the

sensor's temperature coefficient and to scale the calibration curve. Negative

multipliers imply that the sensor has a negative temperature coefficient. The absolute

value of the multiplier scales the calibration curve. For example, the curve for a

Platinum sensor that has 100

of resistance at 0

C may be used with a 1000

sensor by specifying a multiplier of 10.0. Also note that the temperature coefficient

field is only used when the unit is controlling temperature based on the sensor units of

Volts or Ohms.

Units

is an enumeration field that identifies the primitive units used by the sensor’s

calibration curve. Choices are Volts, Ohms and LogOhm. LogOhm selects the base

ten logarithm of ohms and is useful with sensors whose resistance vs. temperature

curve is logarithmic.

The Calibration Curve Edit menu

From this screen, the user can input individual entries into a sensor calibration curve.

Note that these curves can have up to 200 points requiring the entry of 400 floating

point numeric values. For lengthy curves, you may want to consider using one of the

remote interfaces. Cryocon provides a free PC utility that uploads or downloads

curves which can be created by a text editor.

67