9365200990 Rev F

BE1-CDS240 BESTlogic Programmable Logic

7-13

USER INPUT AND OUTPUT LOGIC VARIABLE NAMES

Assigning meaningful names to the inputs and outputs makes sequential events reports easier to

analyze. Input and output logic variable names are assigned by typing them into the appropriate text box

on the related

BESTCOMS

screen. All of the BE1-CDS240’s inputs, outputs, and 43 switches have labels

that can be edited. Table 7-2 shows the range and purpose of each label. Alternately, labels may be

edited using the SN-ASCII command.

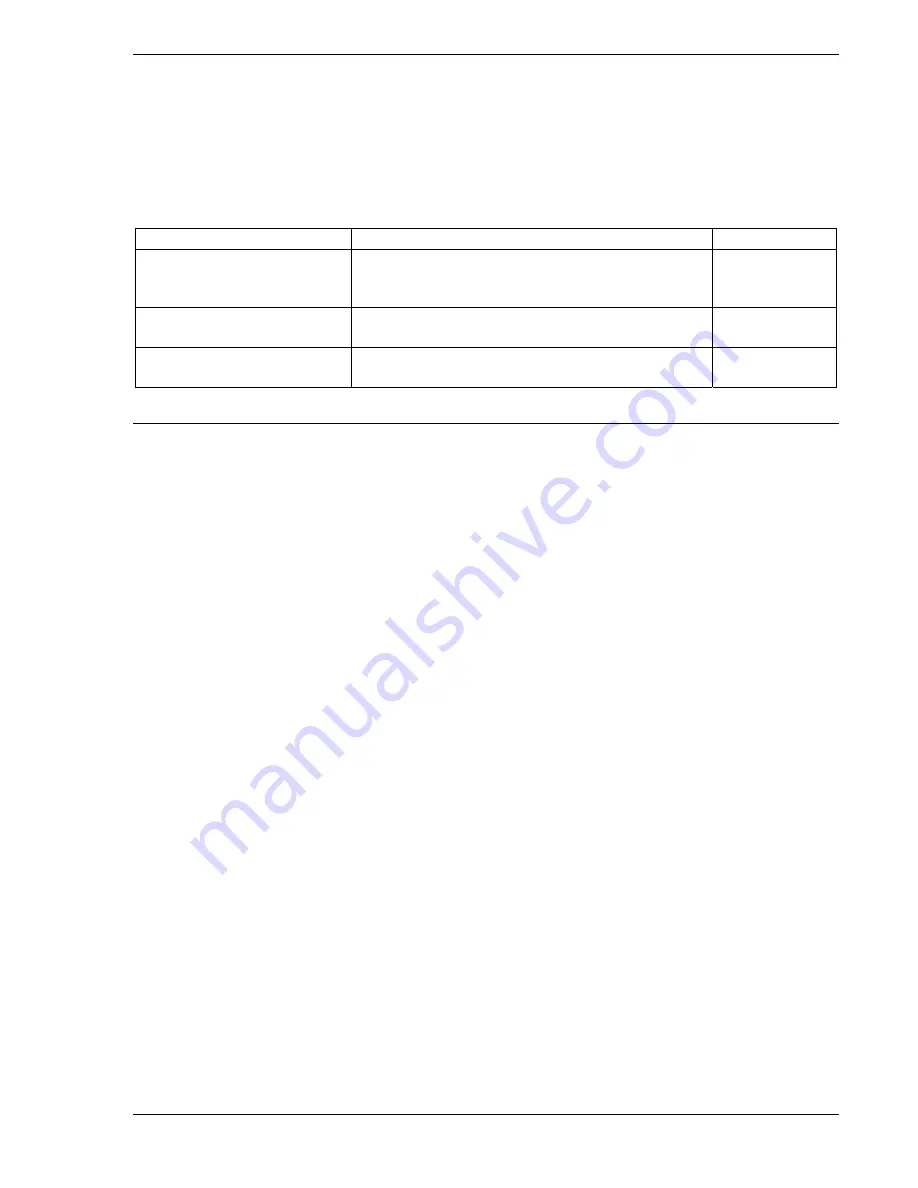

Table 7-2. Programmable Variable Name Setting

Settings Range/Purpose

Default

Name/Label

1 to 10 characters.

User name to replace <var> in the RS report.

INPUT_x

SWITCH_x43

VOx_LABEL

True/Energized State

1 to 7 characters.

Used to replace default labels.

TRUE

False/De-Energized State

1 to 7 characters.

Used to replace default labels.

FALSE

BESTLOGIC APPLICATION TIPS

When designing a completely new logic scheme, logic evaluation order should be considered. Contact

sensing inputs are evaluated first, then the function elements, and then the virtual outputs. VO15 is

evaluated first and VOA is evaluated last. If a virtual output is used in a logic expression to control

another virtual output, the virtual output used in the expression should be numerically higher. Otherwise,

a logic expression for a numerically smaller virtual output won't be available to a numerically higher virtual

output until the next processing interval. Logic is evaluated every quarter-cycle.

When designing custom protection schemes, avoid confusion by maintaining consistency between input

and output functions in the custom scheme and the preprogrammed schemes.

OUT3 through OUT14 have normally open contacts (coil is de-energized). OUT1 and 2 are form C and

have one normally open and one normally closed contact. Normally open contacts can be used as

normally closed outputs by inverting the logic expressions that drive them. Inverting an output logic

expression causes the coil to be energized with the contacts closed in the normal state. Caution should

be taken with normally closed contact logic because there are no shorting bars to maintain the closed

condition if the draw-out assembly is removed from the chassis. In applications where a normally closed

output is needed even when the electronics are removed, a normally open contact from the relay can be

used to drive a low-cost auxiliary relay. The normally closed output of the auxiliary relay will maintain the

closed output when the draw-out assembly is removed from the case. Alternately, an external switch can

be used to short across a normally closed relay output when the draw-out assembly is removed. Extra

care is required to ensure that the switch is closed prior to removing the draw-out assembly and that the

switch is open after the relay is placed back in service.

Several links between the programmable alarms function and BESTlogic programmable logic allow alarm

functions to be used in a logic scheme and programmable logic functions to be used in the alarm

reporting function.

Programmable alarm settings for Major, Minor, and Logic alarms drive BESTlogic variables ALMMAJ,

ALMMIN, and ALMLGC. These variables can be used in logic expressions to control logic when an alarm

is active.

Virtual outputs VO13, VO14, and VO15 are driven by BESTlogic expressions. These three logic variables

are also available in the programmable alarm function. Virtual outputs can also be assigned user

programmable labels (described previously). With this feature, a logic condition can be designed and

used for an alarm. The virtual output label would then be reported in the alarm reporting function.

Summary of Contents for BE1-CDS240

Page 2: ......

Page 8: ...vi BE1 CDS240 Introduction 9365200990 Rev F This page intentionally left blank ...

Page 38: ...1 28 BE1 CDS240 General Information 9365200990 Rev F This page intentionally left blank ...

Page 40: ...ii BE1 CDS240 Quick Start 9365200990 Rev F This page intentionally left blank ...

Page 152: ...ii BE1 CDS240 Metering 9365200990 Rev F This page intentionally left blank ...

Page 226: ...iv BE1 CDS240 Application 9365200990 Rev F This page intentionally left blank ...

Page 286: ...ii BE1 CDS240 Security 9365200990 Rev F This page intentionally left blank ...

Page 290: ...9 4 BE1 CDS240 Security 9365200990 Rev F This page intentionally left blank ...

Page 292: ...ii BE1 CDS240 Human Machine Interface 9365200990 Rev F This page intentionally left blank ...

Page 306: ...10 14 BE1 CDS240 Human Machine Interface 9365200990 Rev F This page intentionally left blank ...

Page 308: ...ii BE1 CDS240 ASCII Command Interface 9365200990 Rev F This page intentionally left blank ...

Page 342: ...11 34 BE1 CDS240 ASCII Command Interface 9365200990 Rev F This page intentionally left blank ...

Page 349: ...Figure 12 5 Horizontal Rack Mount Front View 9365200990 Rev F BE1 CDS240 Installation 12 5 ...

Page 361: ...Figure 12 17 Typical DC Connection Diagrams 9365200990 Rev F BE1 CDS240 Installation 12 17 ...

Page 372: ...12 28 BE1 CDS240 Installation 9365200990 Rev F This page intentionally left blank ...

Page 468: ...13 92 BE1 CDS240 Testing and Maintenance 9365200990 Rev F This page intentionally left blank ...

Page 512: ...14 42 BE1 CDS240 BESTCOMS Software 9365200990 Rev F This page intentionally left blank ...

Page 544: ...ii BE1 CDS240 Terminal Communication 9365200990 Rev F This page intentionally left blank ...

Page 550: ...ii BE1 CDS240 Settings Calculations 9365200990 Rev F This page intentionally left blank ...

Page 578: ...D 28 BE1 CDS240 Settings Calculations 9365200990 Rev F This page intentionally left blank ...

Page 579: ......