EDH0162En1040 – 06/99

8.20

MM4005

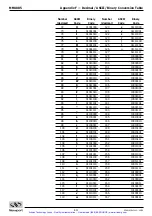

Appendix D — Motion Program Examples

Example 2

In the previous example, to generate the diagonal line (the third motion

segment) both axes must move simultaneously. This is achieved by taking

two special precautions: the commands are placed on the same line to

insure a good start synchronization and the velocities are modified such

that the motions will end in the same time.

But, if you would measure very accurately the precision of this diagonal

line, you would notice some errors due to imperfect start synchronization

and an incorrect acceleration ratio. In other words, we achieved this dual-

axes motion with two independent single-axis motions.

To eliminate these motion errors, we need to use the axes synchronization

(linear interpolation) feature. The improved program will have the follow-

ing listing:

2XX

Erase program #2, if it exists.

2EP

Enter programming mode and store all entries as

program #2.

1VA4

Set velocity of axis #1 to 4 mm/sec.

1PA10,1WS

Move axis #1 to absolute position 10 mm; wait for

axis #1 to complete motion.

2VA4

Set velocity of axis #1 to 4 mm/sec.

2PA5,2WS

Move axis #2 to absolute position 5 mm; wait for

axis #2 to complete motion.

1SY1,2SY1

Declare axes #1 and #2 synchronized.

1PA0,2PA0,SE,WS

Set axis #1 destination to 0 mm and axis #2 destina-

tion to 0 mm; start synchronous motion; wait for

motion to complete.

1SY0,2SY0

Declare axes #1 and #2 non-synchronized.

2QP

End of program #2; quit programming mode.

Notice that there is no need to set the velocities before the synchronized

(interpolated) motion. The controller automatically calculates them to get the

best accuracy possible, without exceeding the pre-set individual velocities.

Also, when finished with an interpolated motion, always return the axes to

the non-synchronized mode.

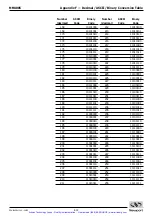

0, 0

10, 0

10, 5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com