840Di-specific data and functions

18.2 Expanded message frame configuration/evaluation of internal drive variables

Manual

Commissioning Manual, 05/2008, 6FC5397–4CP10–4BA0

603

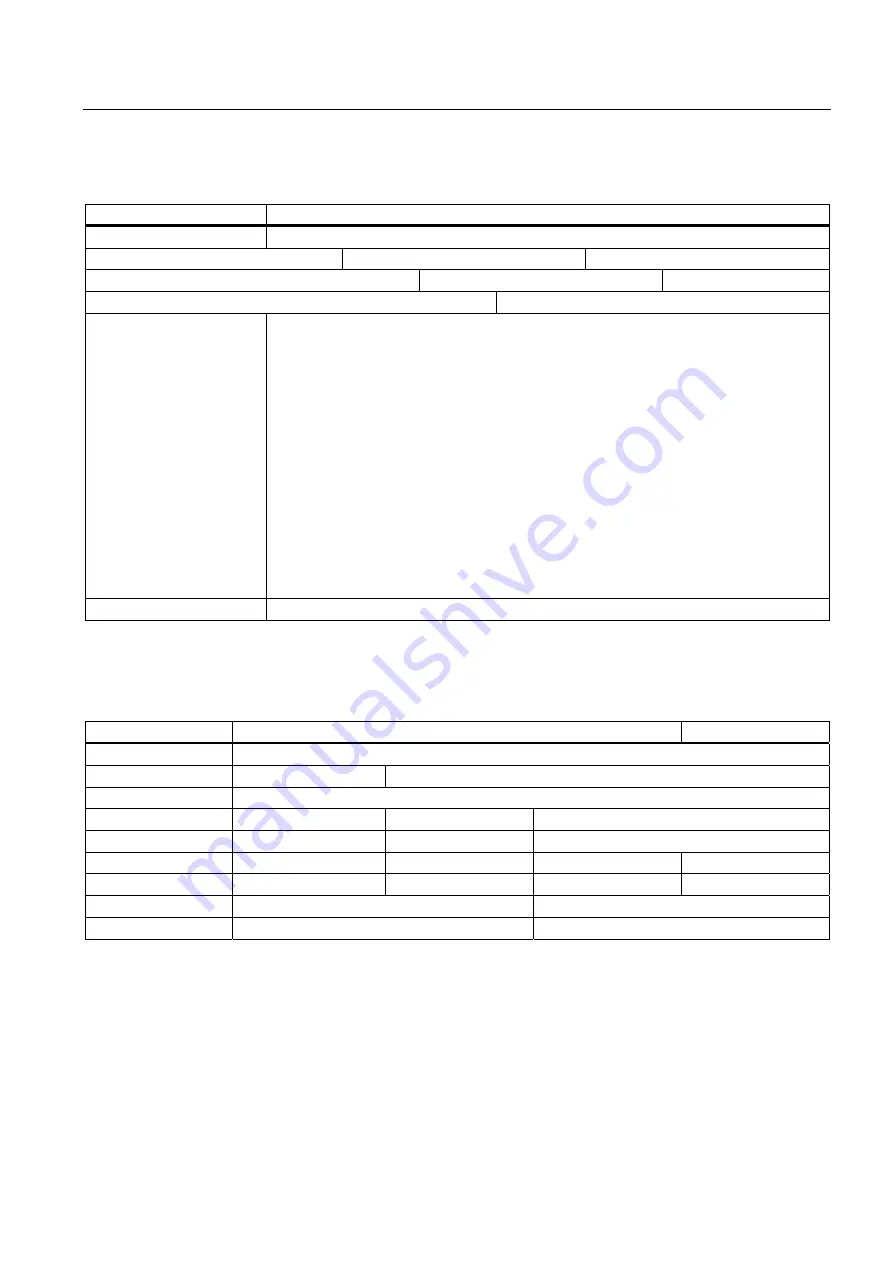

Axis-specific machine data

36730

DRIVE_SIGNAL_TRACKING

MD number

Detection of additional drive actual values

Default setting: 0

Min. input limit: 0

Max. input limit: 4

Changes effective after POWER ON

Protection level: 2/7

unit: -

Data type: BYTE

Valid as of software version: 2.1

Meaning:

DRIVE_SIGNAL_TRACKING (acquisition of additional drive actual values) informs the NC

which additional drive actual values are transferred in the PROFIDrive message frame and

in which system variables they should be stored.

Encoding:

0: No additional drive actual values

1: The following drive actual values are transferred and stored in the system variables:

actual value, system variable

Utilization, $AA_LOAD

Torque setpoint value, $AA_TORQUE

Power, $AA_POWER

Current actual value, t$AA_CURR

2: The total PROFIDrive message frame is stored in a system variable:

actual value, system variable

PROFIDrive message frame, $VA_DP_ACT_TEL

MD irrelevant for ...

---

System variables

Name

$VA_DP_ACT_TEL[n, a]

Description

Word by word mapping of the PROFIBUS message frame from the DP slave

Data type

INTEGER

Value range

[0, 65535]

Indices

n: Array index

Value range

[0,20]

a: Machine axis

Value range

Machine axis identifier

Access

Part program

Synchronized action

OPI

Read

Read

Read

Attributes

Implicit preprocessing stop

Cross-channel

Read

yes

18.2.8

Interrupts

Detailed information on the individual alarms can be found in:

References:

/DA/ Diagnostics Manual

For systems with HMI Advanced you can refer to the online help.